Compressed

air dew point

sampling

Application Note

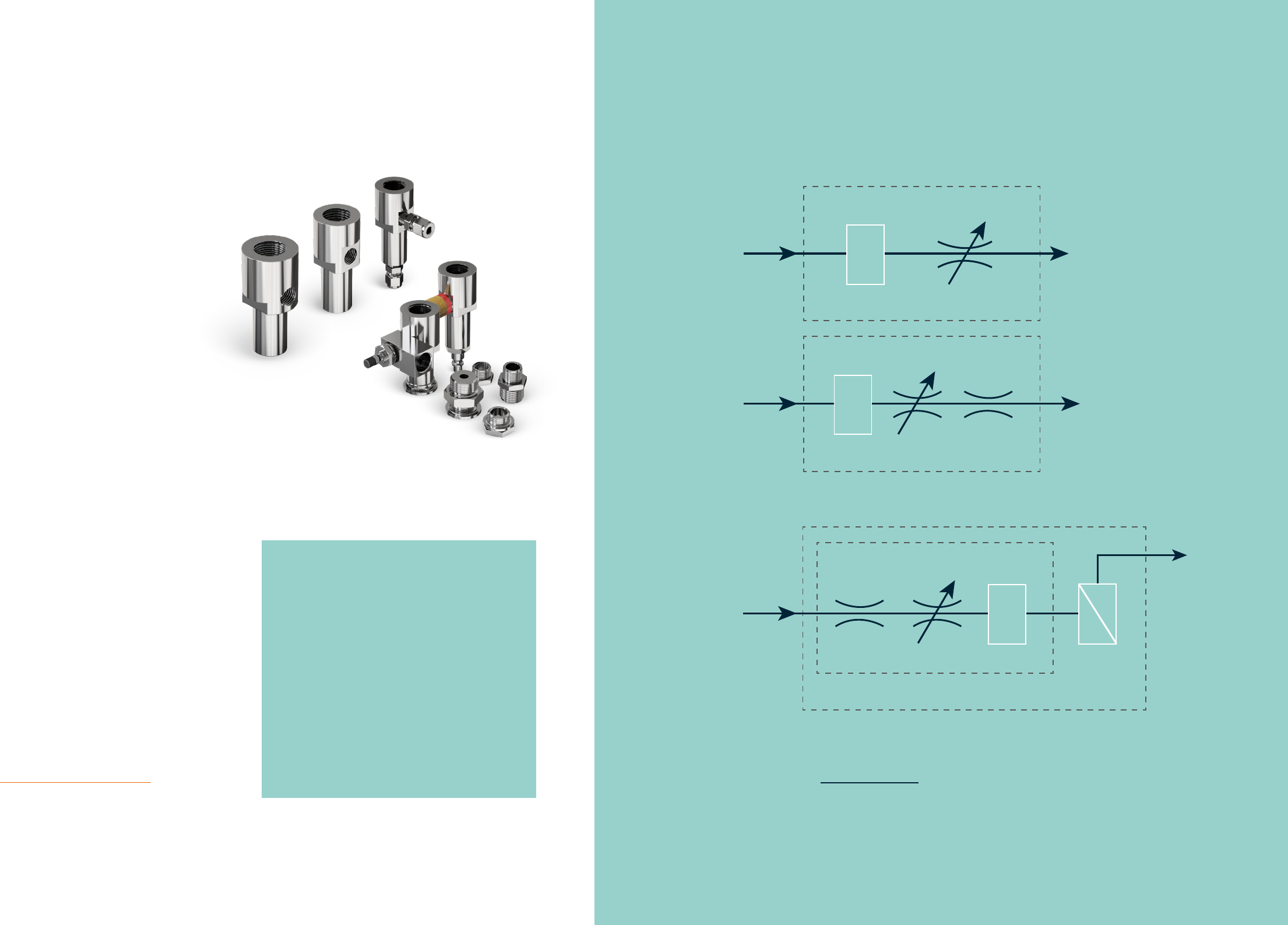

Measurement in the process pressure

Measurement in the atmospheric pressure

DSC74B

DSC74C

DSC74

DSC74B

Diffusion coil

Removable

flowlimiter

Sample gas

inlet

Valve

Sample gas

outlet

Chamber

for DMP74

Sample gas

inlet

Chamber

for DMP74

Valve

Sample gas

outlet

Removable

flowlimiter

Sample gas

inlet

Chamber

for DMP74

Valve

Sample gas

outlet

»

See technical note Dewpoint sampling cells

for DRYCAP® products for details

Why Vaisala?

Vaisala is a global leader in measurement

instruments and intelligence for climate

action. We equip our customers with devices

and data to improve resource efficiency, drive

energy transition, and care for the safety and

well-being of people and societies worldwide.

With almost 90 years of innovation and

expertise, we employ a team of over 2,300

experts committed to taking every measure

for the planet.

Sampling is needed when direct measurement of

the air is undesirable or is simply not feasible. This

may be due to a high process temperature, the

need to protect the sensor from water spikes, the

added convenience of installing and removing the

instrument from a pressurized process without

shutting down the line or wanting to make the

measurement in a more convenient location.

To get a representative sample of the process

gas and avoid potential sources of error caused

by incorrect sampling practices, the following

aspects should be considered.

»

Visit vaisala.com/compressedair for more

information about the products.

Compressed air

dew point sampling

21

01

Pressure

It is important to keep in mind that changing the

gas pressure changes the dew point temperature

of the gas. If the sensor is at a different pressure

than the process itself, an error of several tens of

degrees dew point may be apparent. Generally,

the measurement should be taken at the actual

system pressure to avoid pressure drops in the

sampling system. Exceptions can sometimes be

made when standards require reporting the dew

point at ambient pressure, thus excluding the

effect of pressure fluctuations.

02

Condensing water

When the need for sampling is due to a high

process gas temperature prohibiting direct

measurement, it is important to ensure that the

dew point level of the process is lower than the

ambient temperature to which the sample gas is

cooled in the sampling line. This prevents water

vapor in the sample from reaching saturation

causing liquid water to form in the sample line.

In cases where the dew point is higher

than ambient temperature, either a direct

measurement or a heated sampling line

is required.

03

Leak tightness

& materials

Due to the very low level of humidity typically

found in compressed air and gas systems, dew

point measurements are highly sensitive to even

the smallest leaks in the system. Consequently,

the importance of having a leak-tight sampling

system is critical. All connections should be tight

and sealed correctly. For tapered threads like NPT,

use of Teflon tape is recommended. For straight

thread connections such as G 1/2”, the sealing

washer provided with the instrument should be

installed between the probe and the sample cell.

Careful consideration should always be given to

the sampling system’s material of construction

since water vapor diffusion through the pipe

or tubing walls can occur. The piping should

preferably be made of metal, e.g., stainless steel

with a good surface finish. Hygroscopic material

such as rubber hose and plastics is undesirable

and should be avoided. PTFE or Teflon is one

exception that is a rather vapor tight plastic and

can be used down to a dew point level of about –

40 °C (-40 °F).

Sample tubing should be as short in length as

possible and “dead ends” should be avoided. Also

minimizing the number of connections helps in

avoiding leaks. If possible, prepare the sampling

system for the measurement by purging it with

the dry process gas sufficiently to ensure a faster

stabilization and response time.

04

Flow rate

considerations

Stagnant air can be a problem for a few reasons:

1. A representative sample of the process air may

not be obtained.

2. Response time may be dramatically impaired.

3. The risk of ambient air leaking or diffusing

through sampling materials increases.

4. Back diffusion of ambient water vapor through

the outlet port of the sample cell can occur.

•

Using a dew point sensor that is not dependent

on flow rate is strongly recommended. Although

higher flow rates generally improve the sensor

response time, flows of 1-2 l/min (0.035-

0.7 ft3/min) are typically enough for high-

quality sensors.

43

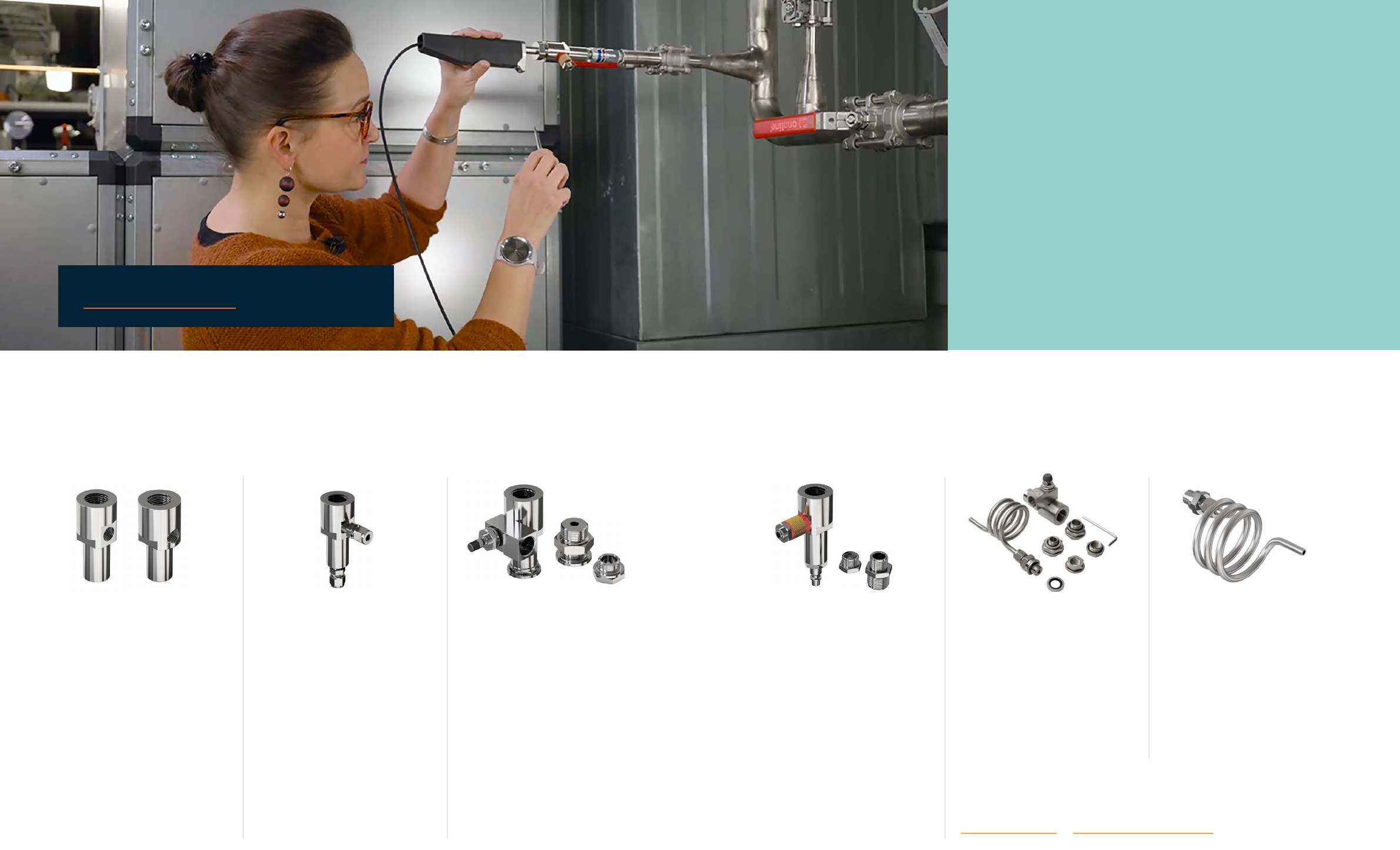

DMT242SC & SC-025NPT

basic models

Basic sample cells consisting of just the main

sampling body.

Suitable for users requiring only a

sample cell for a probe and doing further

assembly themselves

(piping into inlet and outlet, valves and

possible flow meter).

The inlet and outlet are female threaded

sample connectors.

DMT242SC: inlet G3/8” ISO, outlet G1/4” ISO

SC-025NPT: inlet 1/4”NPT, outlet 1/4”NPT

DSC74

quick connector, leak screw and

thread adapters

Contains an adjustable leak screw that

maintains the compressed air system

pressure at the cell (the leak screw is

opened and closed with a screwdriver

and should be turned 1/2 turn which

approximates a 1 l/min flow rate.)

Comes with a quick connector that fits

industry standard compressed air line

connectors. This allows for easy installation

and detachment of the dew point

transmitter without having to shut down

the process.

Alternative ways to connect are through

the two different thread adapters - R3/8”

to R1/2” and G3/8” to G1/4” ISO – that are

supplied with each DSC74 cell.

DMT242SC2

Swagelok® connectors for 1/4” tubing

Same body as DMT242SC, but with welded

Swagelok® connectors at both the inlet and

outlet that fit directly to 1/4” tubing.

To fit 6 mm tubing to the connectors,

an adapter such as Swagelok® Reducer

SS-6M0-R-4 (not supplied by Vaisala) can

be used.

Can be used with DMCOIL - Shown below.

DSC74CSP

two-pressure sampling cell with coil

Designed for the most critical

measurements at atmospheric pressure

The diffusion coil is connected to the

sampling cell outlet to protect the sensor

from ambient humidity disturbing

the measurement

Used with a ISO1/2” Swagelok connector

DSC74B

two-pressure model for elevated and

atmospheric pressure

Includes inlet/outlet valve and inlet/outlet

connection for gas tubing.

Limits flow rate with a fixed leak screw.

Flow is optimized for pressures 3 ... 10 bar.

Fixed leak screw eliminates the risk

of opening the screw completely and

emptying a gas vessel.

Maximum flow can be increased, if needed,

by removing the leak screw and adjusting

the flow manually with the valve.

Reducing parts supplied (G3/8” -G1/2” or

G3/8” - G1/4”) on the outlet side help to

protect the sensor from ambient humidity

leaking in.

DMCOIL

stainless steel (aisi316l)

Coil accessory – DMT242SC2 required.

Used as a cooling coil in high

temperature gas processes to cool gas

temperature down to a suitable level for

measurement sensors.

For applications where gas pressure is

reduced to ambient pressure prior the

sample cell, it can act as venting coil in gas

outlet to prevent ambient humidity from

disturbing low dew point measurement.

Indigo-compatible probes

and sample cells

Our sample cells are compatible with several of our dew

point measurement instruments that are meant for

different purposes:

• Spot-checking: Vaisala Indigo80 handheld indicator in

combination with DMP80

• Inline process measurement: Vaisala DRYCAP

®

dew point

probe DMP7 (requires SWG12ISO12)

• Original equipment manufacturing: Vaisala DRYCAP

®

dew point probes DMT132, DMT143, DMT143L, DPT146,

and DMT152

• The sample cells can also be used with various previous

generation Vaisala DRYCAP

®

dew point instruments

such as Vaisala DRYCAP

®

dew point instruments DM70,

DMT142, DMT242, DMT347 (SWG12ISO12 required),

and DMT348.

05

»

Order sample cells, spare parts and selected products via

store.vaisala.com or contact our sales experts.

»

See how to spot-check a compressed air system:

vaisala.com/compressedair

65

vaisala.com

This material is subject to copyright protection, with all copyrights retained by Vaisala and its

individual partners. All rights reserved. Any logos and/or product names are trademarks of Vaisala

or its individual partners. The reproduction, transfer, distribution or storage of information

contained in this brochure in any form without the prior written consent of Vaisala is strictly

prohibited. All specifications — technical included — are subject to change without notice.

Ref. B211229EN-E ©Vaisala 2024