Liebert® Air Cooled Condenser

USER MANUAL

Copyright by Vertiv Co. Ltd.

The content in this document is subject to change without notice. All rights, including rights of

translation, reproduced by printing, copying or similar methods, and even of parts, are reserved.

Violators will be liable for damages. All rights, including rights deriving from patent license or

registration of a utility model or design, are reserved. No part of this document may be

reproduced or transmitted in any form or by any means without the prior written consent of

Vertiv Co. Ltd.

Notice

The purchased products, services, and features are stipulated by the contract made between

Vertiv Co., and the customer. All or part of the products, services, and features described in this

document may not be within the purchasing scope or the usage scope. Unless otherwise

specified in the contract, all statements, information, and recommendations in this document

are provided "AS IS" without warranties, guarantees or representations of any kind, either

express or implied. The information in this document is subject to change without notice. Every

effort has been made in the preparation of this document to ensure the accuracy of the

contents, but all statements, information, and recommendations in this document do not

constitute a warranty of any kind, express or implied.

Vertiv Co., Ltd.

• China

Website:www.vertivco.com

E-mail:

Cus

tomer service hotline: 4008876510

• Asia Pacific

Homepage: www.vertivco.com

E-mail:

overseas.support@Vertivco.com

For Technical Support, users may contact the nearest Vertiv Co. local sales office or service

center.

Purpose of the Document

This document applies to the Liebert LSF Air Cooled Condenser used in precision air

conditioners and cooling solutions which maintain an optimal environmental control for

technological ecosystems at minimal operating costs. This document gives an overview of the

technical specifications and parameters. The figures used in this document are for reference

only.

Styling used in this Guide

The styles used in the manual will be defined as mentioned in the following table:

Situation Description

Warning/Danger/Caution

The

Warning/Danger/Caution

note indicates a hazardous or

potentially harmful situation that can result in death or injury. It

also indicates instructions that need to be ad

hered to, failing

which may result in danger and safety issues thereby having an

adverse effect on the reliability of the device and security. Even

for practices not related to physical injury, the content under the

Warning heading is used for precautions which need to be taken

which, otherwise, could result in equipment damage,

performance degradation, or interruption in service.

Note

The

Note

section indicates additional and useful information. It

also calls attention to best practices and industry-best protocols

that are standardized and help make maximum utilization of the

resources at hand. Helpful information related to the product

also comes under the Note heading, helping the users with the

definitions, concepts, and terminologies used in the manual.

Version History

BOM Revision Change

31012725 V1.3

--

TABLE OF CONTENTS

Chapter 1 Overview ............................................................................................ 1

1.1 Classification And Models ..................................................................................................................................... 1

1.2 Model Description ................................................................................................................................................. 1

1.3 Main Components ................................................................................................................................................. 2

1.4 Technical Parameters ........................................................................................................................................... 3

1.4.1 Mechanical Parameters ............................................................................................................................. 3

1.4.2 Mounting Base Dimensions ....................................................................................................................... 4

1.4.3 Parameters of Operating Environment ...................................................................................................... 6

1.4.4 Parameters Of Storage Environment ......................................................................................................... 6

Chapter 2 Installation ....................................................................................... 7

2.1 Moving, Unpacking And Inspection ..................................................................................................................... 7

2.2 Installation Notes ................................................................................................................................................. 8

2.3 Space Requirements ............................................................................................................................................ 9

2.4 Installation Procedures ...................................................................................................................................... 10

Chapter 3 Application of Fan Speed Controller ...........................................13

3.1 Wiring Terminals ................................................................................................................................................. 13

3.2 HMI ..................................................................................................................................................................... 14

3.3 Operation Description Of HMI ........................................................................................................................... 17

3.3.1 Initial Interface ......................................................................................................................................... 17

3.3.2 Main Menu Interface ................................................................................................................................ 17

Chapter 4 Maintenance and Troubleshooting ............................................ 24

4.1 Maintenance ....................................................................................................................................................... 24

4.2 Troubleshooting................................................................................................................................................. 26

Appendix Circuit Diagram ........................................................................... 28

Vertiv I Liebert Air Cooled Condenser I User Manual 1

Chapter 1 Overview

This chapter introduces the classification and models, model description, main components

and technical parameters of the Liebert condenser (condenser for short).

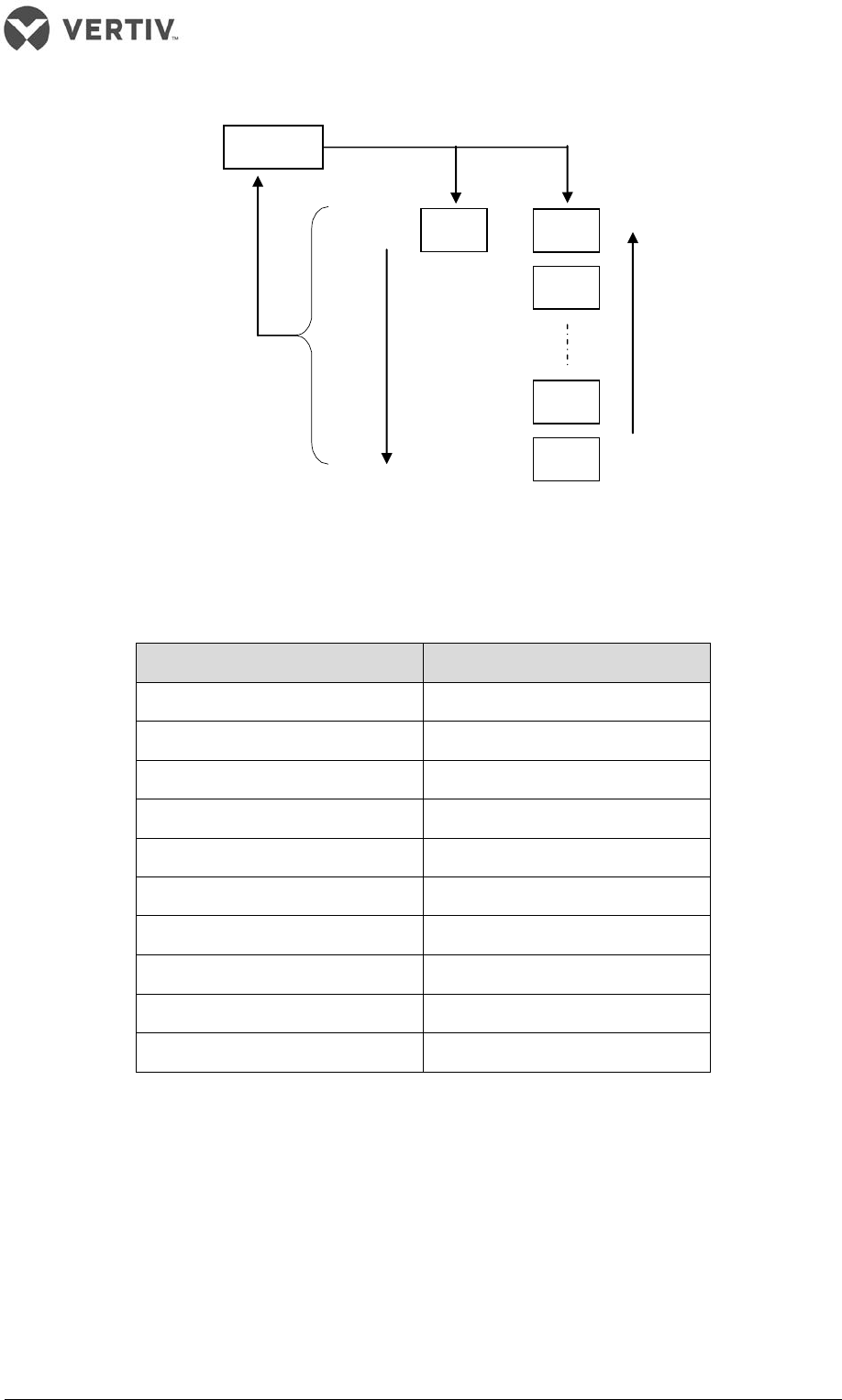

1.1 Classification And Models

The condenser is classified into two types: single circuit and dual circuit. The single circuit has

a set of discharge/liquid pipe to match the single refrigeration system of indoor unit. The dual

circuit has two sets of discharge/liquid pipes to match the two separate refrigeration systems

of indoor unit.

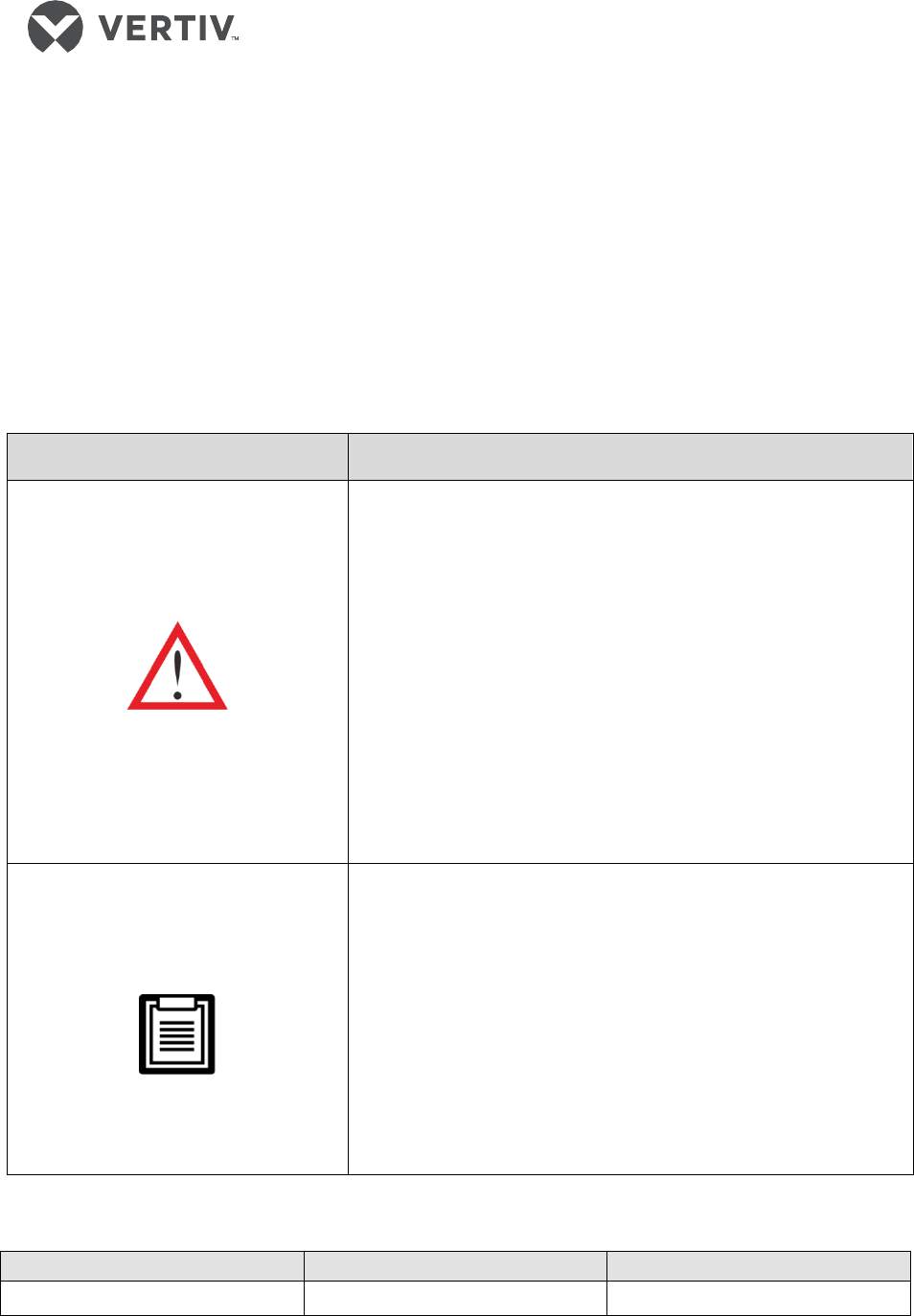

The condenser is available in 17 models. The classification and models are listed in Table 1-1.

Table 1-1 Condenser models

R22/R407C

refrigeration

Single

circuit

LSF24

-T

LSF32-

T

LSF38

-T

LSF42

-T

LSF52-

T

LSF62

-T

LSF70

-T

LSF76

-T

LSF85

-T

Dual

circuit

LDF42

-T

LDF52

-T

LDF62

-T

LDF70

-T

LDF76

-T

LDF85

-T

R410A

refrigeration

Single

circuit

LSF24

-R3

LSF32-

R3

LSF38

-R3

LSF42

-R3

LSF52-

R3

LSF62

-R3

LSF70

-R3

LSF76

-R3

LSF85

-R3

Dual

circuit

LDF42

-R3

LDF52

-R3

LDF62

-R3

LDF70

-R3

LDF76

-R3

LDF85

-R3

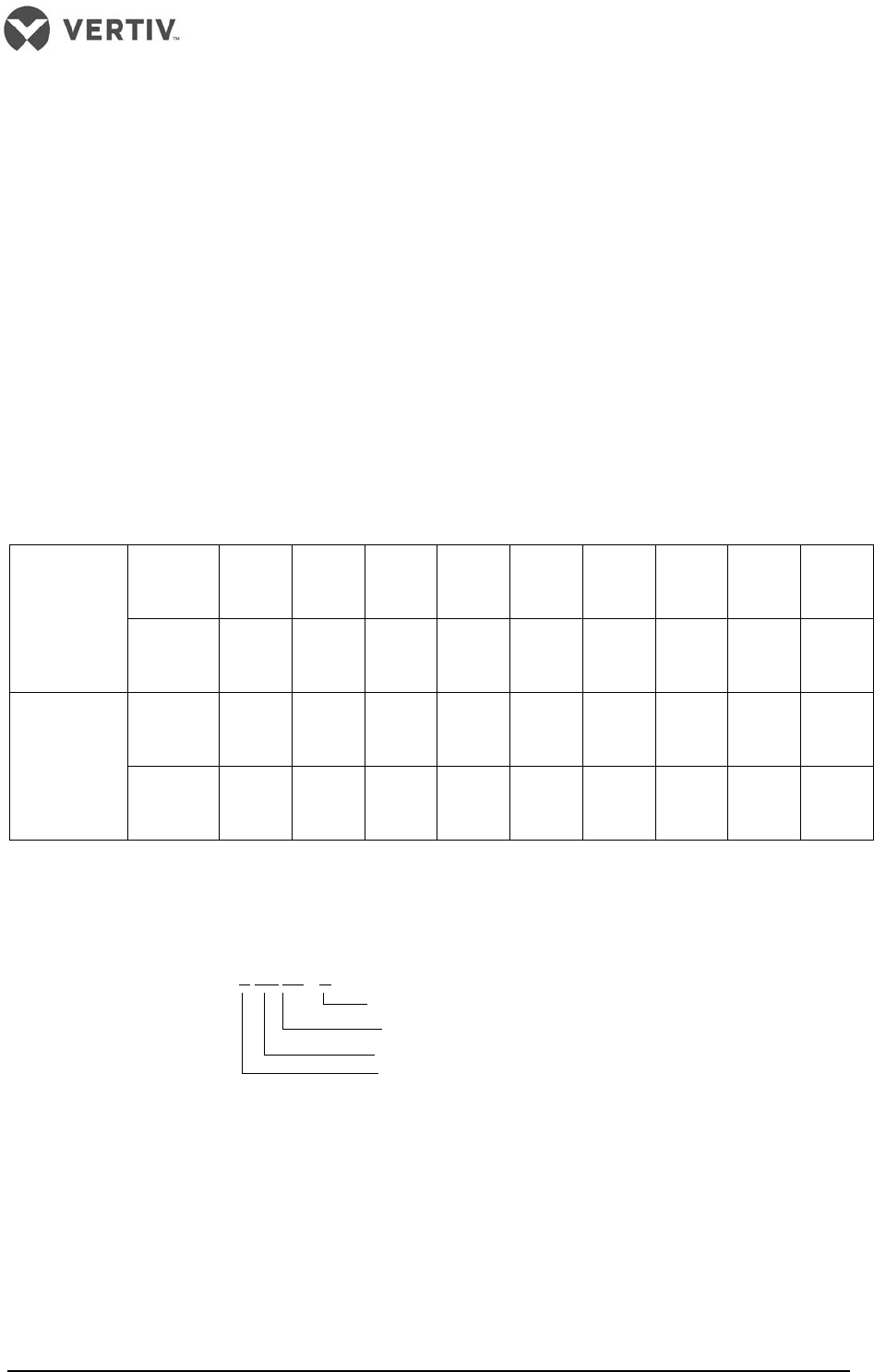

1.2 Model Description

Taking LSF62 for example, the model description of the condenser is shown in Figure 1-1.

L SF 62 -T

Liebert

SF: single circuit with fan speed controller

DF: dual circuit with fan speed controller

Model code

-T R22/R407C System

-R3 R410A system

Figure 1-1 Model description

Vertiv I Liebert Air Cooled Condenser I User Manual 2

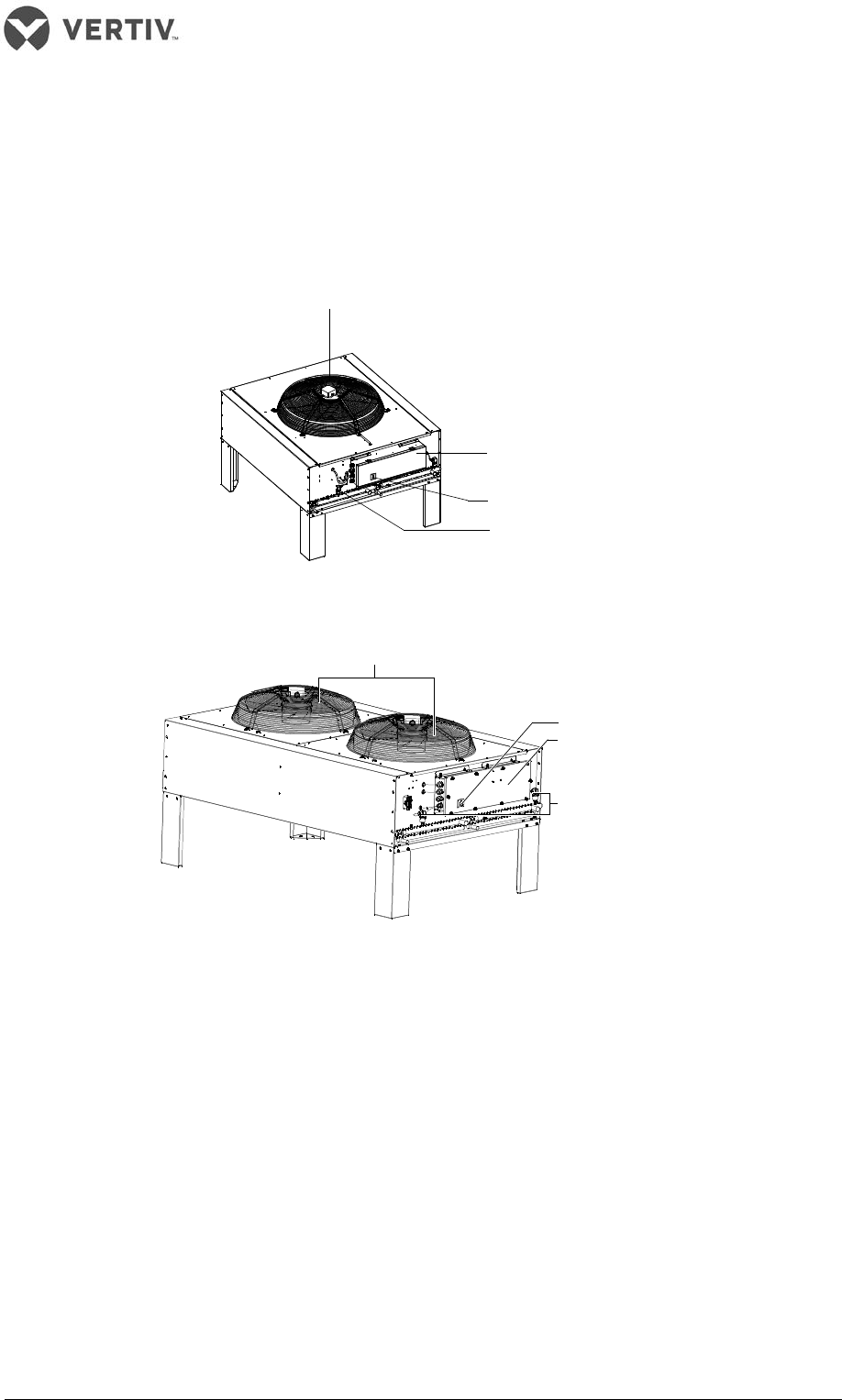

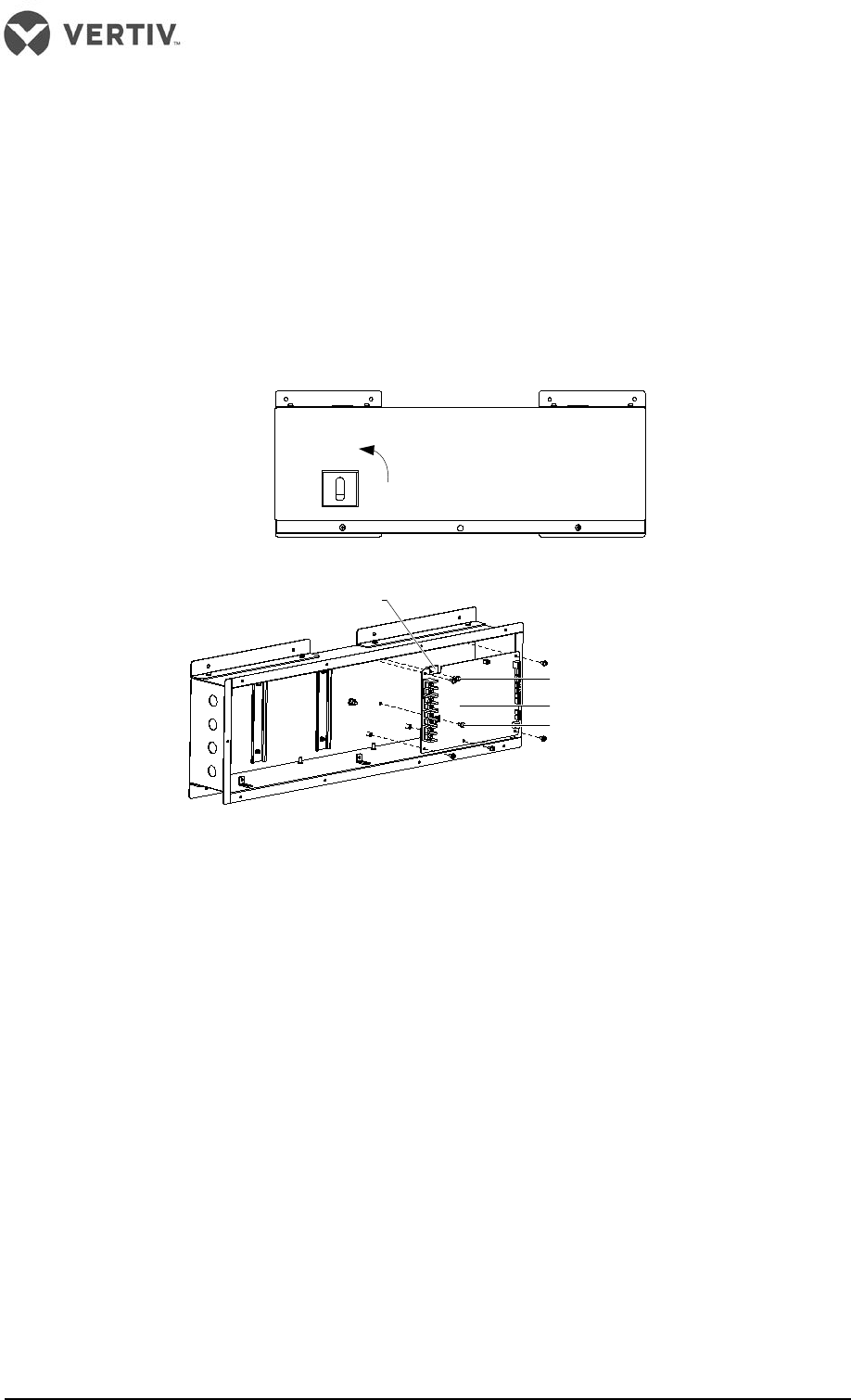

1.3 Main Components

The main components of the condenser include the heat exchanger, fan, fan speed controller

and pressure sensor. The heat exchanger is inside the condenser, and the appearance and

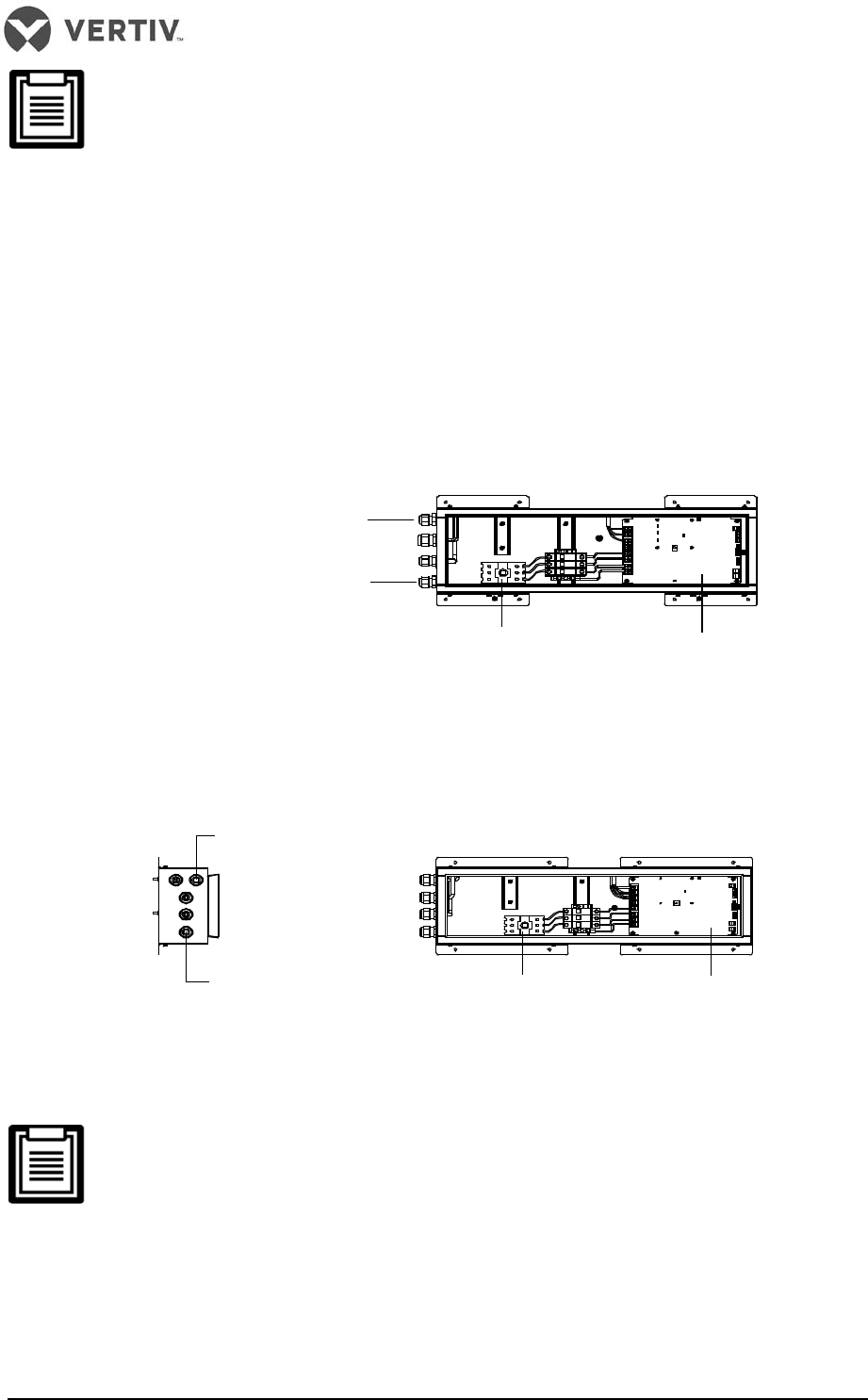

position of other components are shown in Figure 1-2 and Figure 1-3.

Fan

Figure 1-2 Condenser (single fan, single circuit)

Fans

Isolation switch

Electrical control box (with a fan speed

controller inside)

Pressure sensors

Figure 1-3 Condenser (double fans, dual circuit)

Electrical control box (with a fan speed

controller inside)

Isolation switch

Pressure sensors

Vertiv I Liebert Air Cooled Condenser I User Manual 3

1.4 Technical Parameters

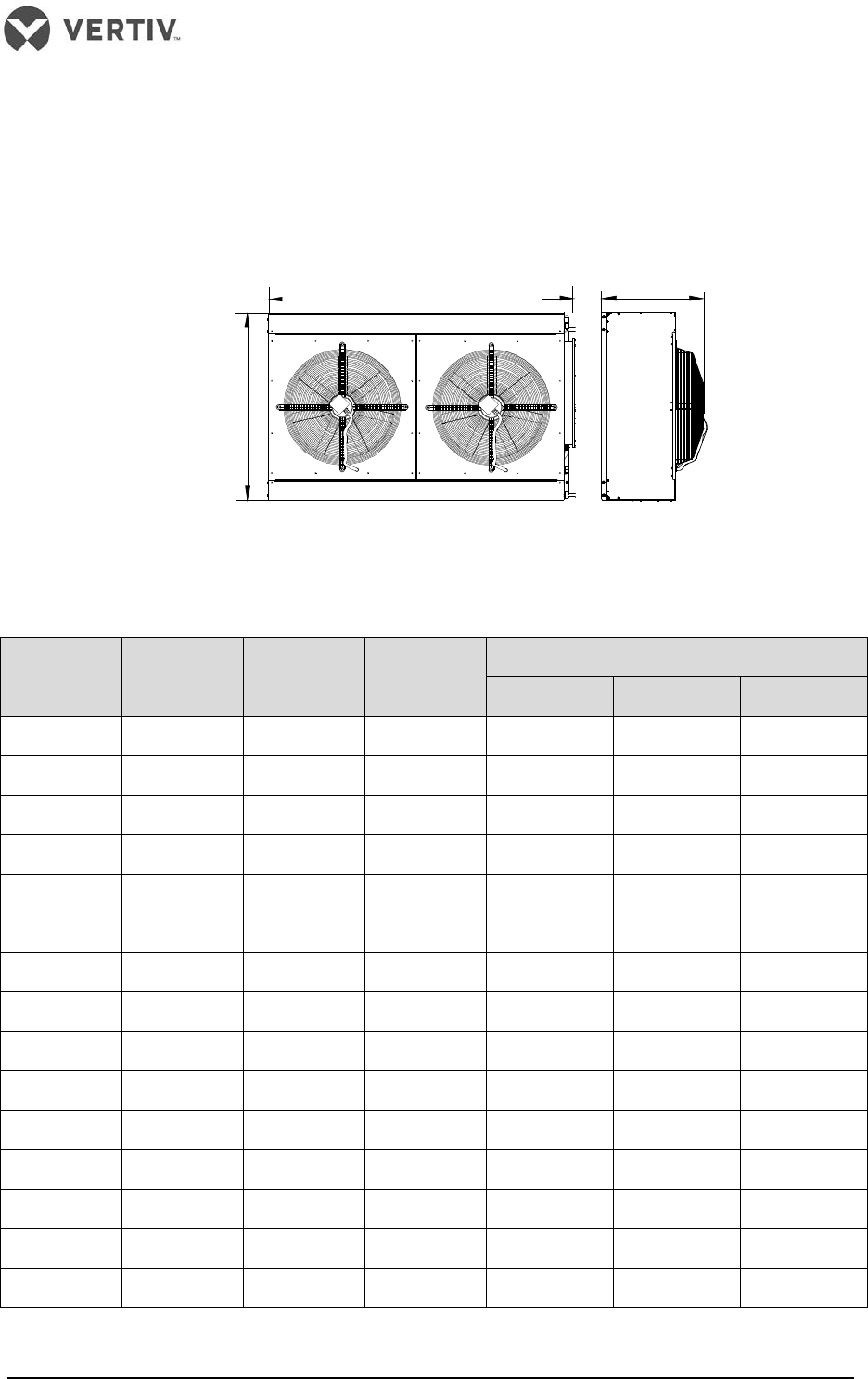

1.4.1 Mechanical Parameters

The condenser structure is shown in Figure 1-4. The mechanical parameters of each model are

listed in Table 1-2.

W

H

L

L

H

Front view

Side view

Figure 1-4 Structure (double fans) (unit: mm)

Table 1-2 Mechanical parameters

Model Weight (kg)

Fan diameter

(mm)

Fan number

Dimension (mm)

L H W

LSF24 105 710 1 1384 990 689

LSF32 110 710 1 1384 990 689

LSF38 120 800 1 1384 990 695

LSF42 130 800 1 1584 1273 695

LSF52 140 800 1 1584 1273 695

LSF62 150 710 2 1884 1273 689

LSF70 150 710 2 1884 1273 689

LSF76 220 800 2 2384 1273 695

LSF85 230 800 2 2384 1273 695

LDF42 130 800 1 1584 1273 695

LDF52 140 800 1 1584 1273 695

LDF62 160 710 2 2084 1273 689

LDF70 160 710 2 2084 1273 689

LDF76 220 800 2 2384 1273 695

LDF85 230 800 2 2384 1273 695

Vertiv I Liebert Air Cooled Condenser I User Manual 4

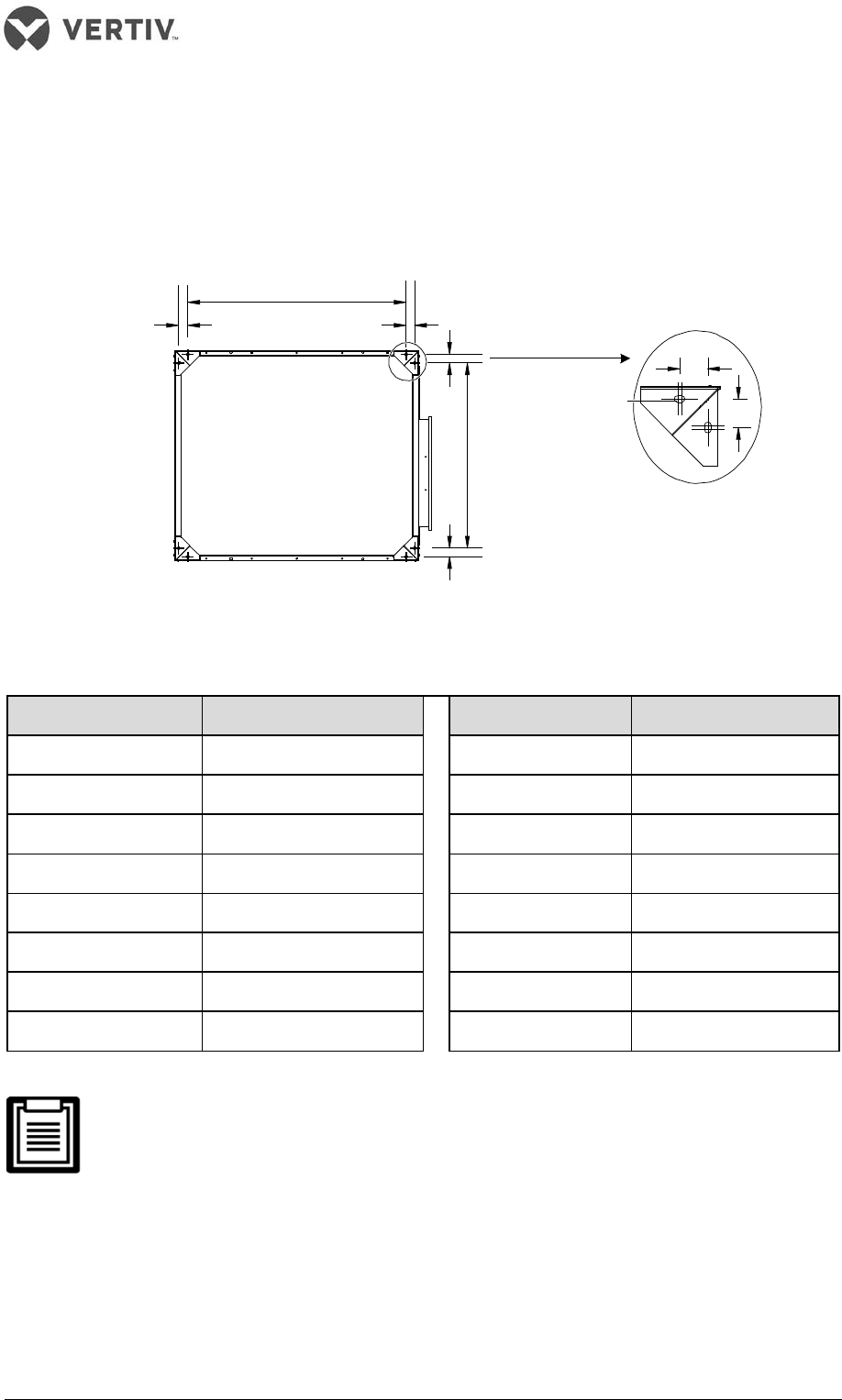

1.4.2 Mounting Base Dimensions

Mounting base dimensions for horizontal installation

The mounting base figure for horizontal installation is shown in Figure 1-5, and the specific

mounting base dimensions of each model are listed in Table 1-3.

D

D

L'

D

H'

D

Amplified part figure

D

D

Installation holes

(8 holes in total )

Figure 1-5 Mounting base figure for horizontal installation (unit: mm)

Table 1-3 Mounting base dimensions for horizontal installation (unit: mm)

Model Dimension (L' × H' × D) Model Dimension (L' × H' × D)

LSF24 1126 × 837 × 53 LSF85 2126 × 1120 × 53

LSF32 1126 × 837 × 53 LDF42 1326 × 1120 × 53

LSF38 1126 × 837 × 53 LDF52 1326 × 1120 × 53

LSF42 1326 × 1120 × 53 LDF62 1826 × 1120 × 53

LSF52 1326 × 1120 × 53 LDF70 1826 × 1120 × 53

LSF62 1626 × 1120 × 53 LDF76 2126 × 1120 × 53

LSF70 1626 × 1120 × 53 LDF85 2126 × 1120 × 53

LSF76 2126 x 1120 x 53

The installation holes are long and flat holes. It is recommended to use M10 × 20

bolts to fix the mounting base.

Vertiv I Liebert Air Cooled Condenser I User Manual 5

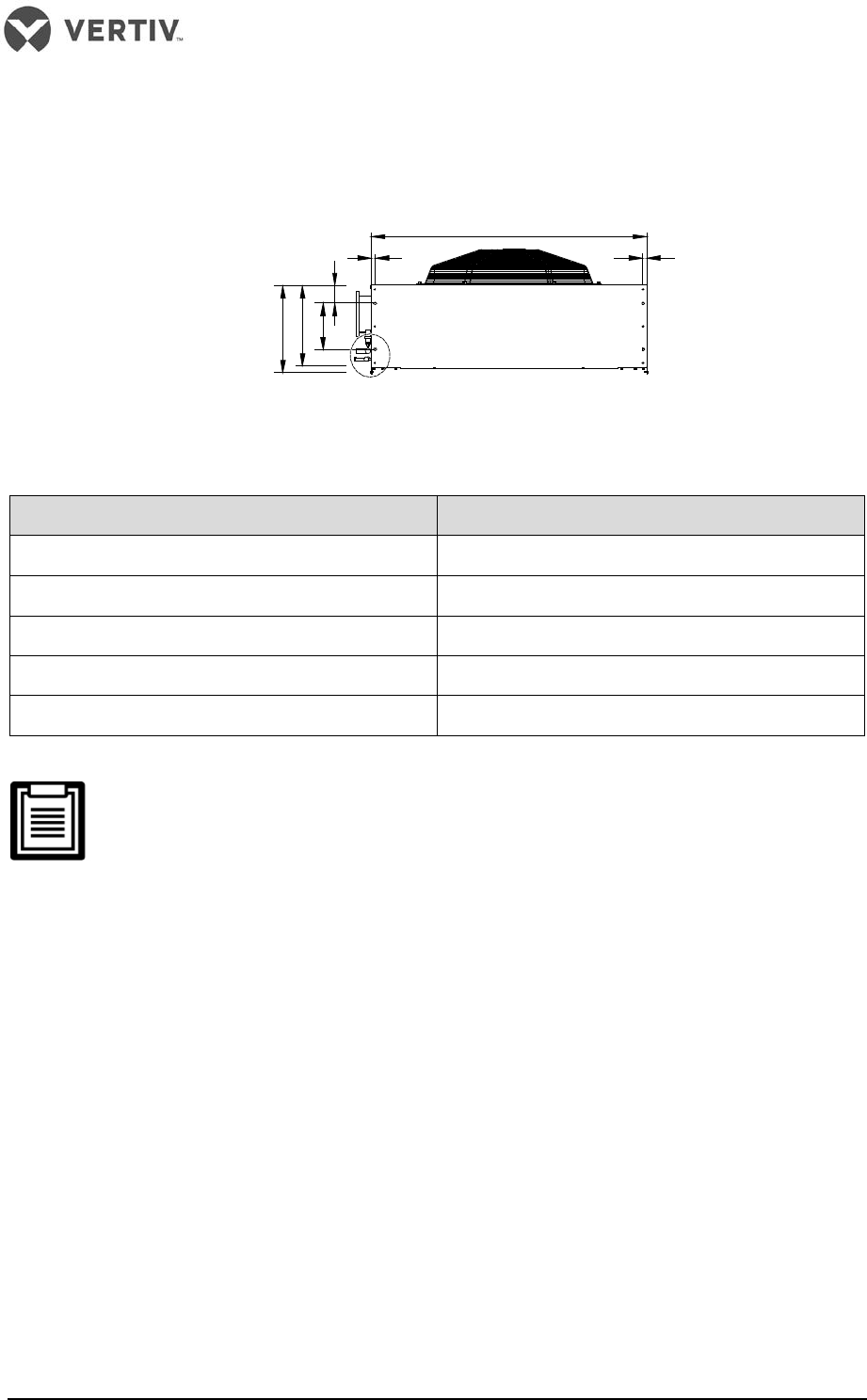

Mounting base dimensions for vertical installation

The mounting base figure for vertical installation is shown in Figure 1-6, and the specific

mounting base dimensions of each model are listed in Table 1-4.

250

102

452

490

a

2020

Figure 1-6 Mounting base figure for vertical installation (top view) (unit: mm)

Table 1-4 Mounting base dimensions for vertical installation (unit: mm)

Model Dimension ‘a’

LSF24, LDF32, LSF38 1280

LSF42, LDF42, LSF52, LDF52 1480

LSF62, LSF70 1780

LDF62, LDF70 1980

LSF76, LDF76, LSF85, LDF85 2280

1

.

T

he installation holes are long and flat holes. It is recommended to use M10 × 20

bolts to fix the mounting base.

2.

T

he upper condenser must be installed on a rack during vertical installation, an

d

t

he cushion pads should be installed between the condenser and the rack for

reducing vibration. It is prohibited to stack two condensers through bolt

connection.

Vertiv I Liebert Air Cooled Condenser I User Manual 6

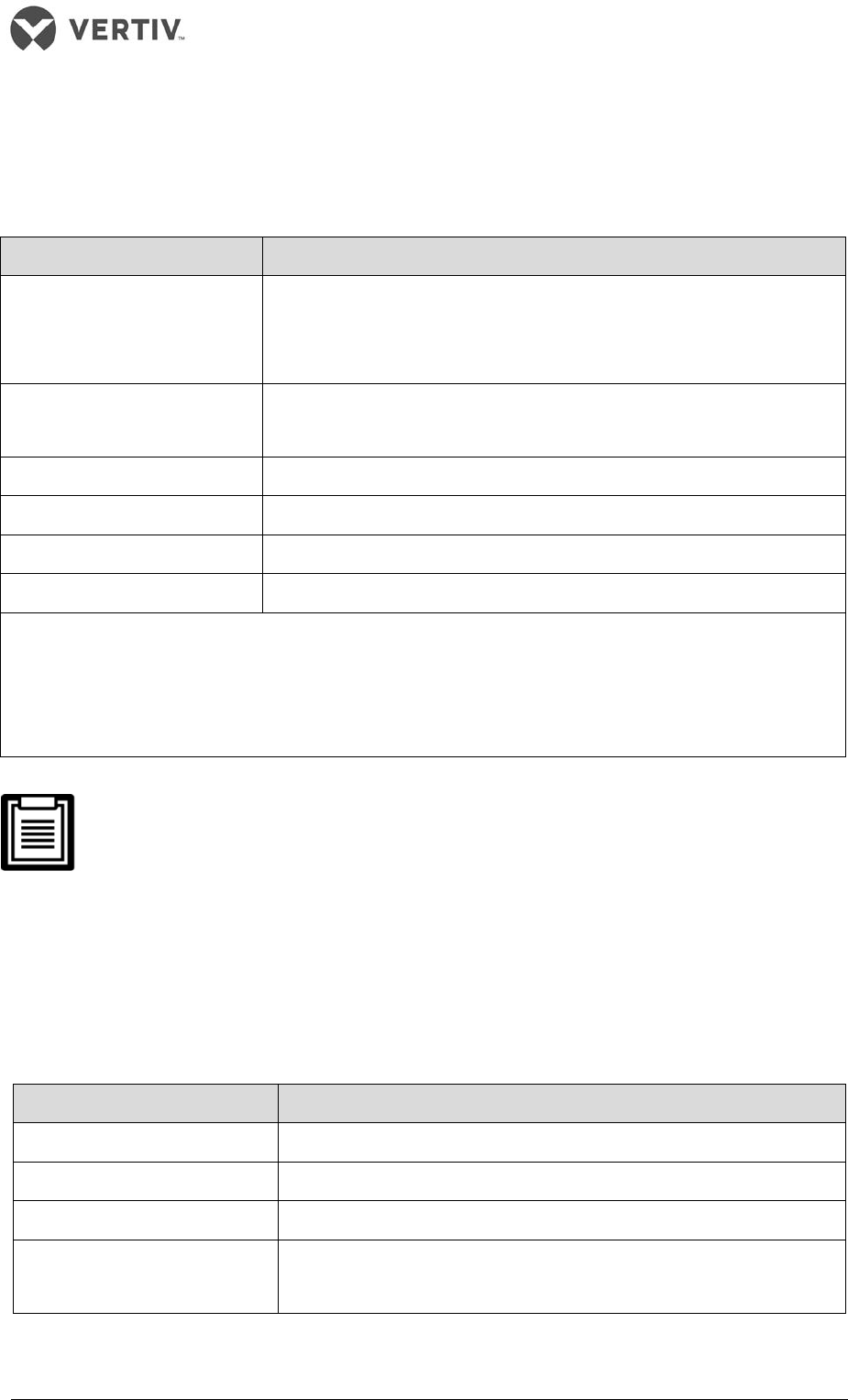

1.4.3 Parameters of Operating Environment

Refer to Table 1-5 for parameters of operating environment.

Table 1-5 Parameters of operating environment

Item Requirement

Installation position

The standard equivalent distance between the indoor unit and the condenser

is 30m. Vertical difference* ∆H: -5m ≤ ∆H ≤ 20m. Installation mode: horizontal

or vertical mode

Ambient temperature

Outdoor temperature: -20°C ~ +45°C. Low temperature accessories are

required if the temperature is between -35°C and -20°C

Ambient relative humidity Outdoor humidity: 5%RH ~ 95%RH

Operation power 400V ± 10%, 50/60Hz

Altitude ≤ 1000m. Derating is required if the altitude exceeds 1000m

Protection level Electrical control box: IP55; unit: IP20; fan motor: IP54

Note*:

Condenser fins have a corrosion resistant coating designed to provide maximum life expectancy for the heat

exchanger and protect the aluminium fins from harsh environments. The high performance coating has been

tested for 2000 hours exposure to a 5% neutral salt spray test in accordance with ASTMB117 without impact to the

coating

When the equivalent distance between the indoor unit and the condenser exceeds

30m, refer Refrigerant Tubing System in Liebert LSF Air Conditioner Technical

Manual for the requirement of the line equivalent length.

1.4.4 Parameters Of Storage Environment

Refer to Table 1-6 for parameters of storage environment.

Table 1-6 Parameters of storage environment

Item Requirement

Storage environment Clean indoor environment with good ventilation and no dust

Ambient temperature -40°C ~ +70°C

Ambient relative humidity 5%RH ~ 85%RH

Storage time

The total storage time should not exceed 6 months. Otherwise, the

performance needs to be re-calibrated

Vertiv I Liebert Air Cooled Condenser I User Manual 7

Chapter 2 Installation

This chapter introduces the moving, unpacking, inspection, installation notes, space

requirements and installation procedures.

2.1 Moving, Unpacking And Inspection

Moving

It is recommended to use the mechanical transport equipment such as a forklift or a crane

when unloading and transferring the condenser closest to the installation site.

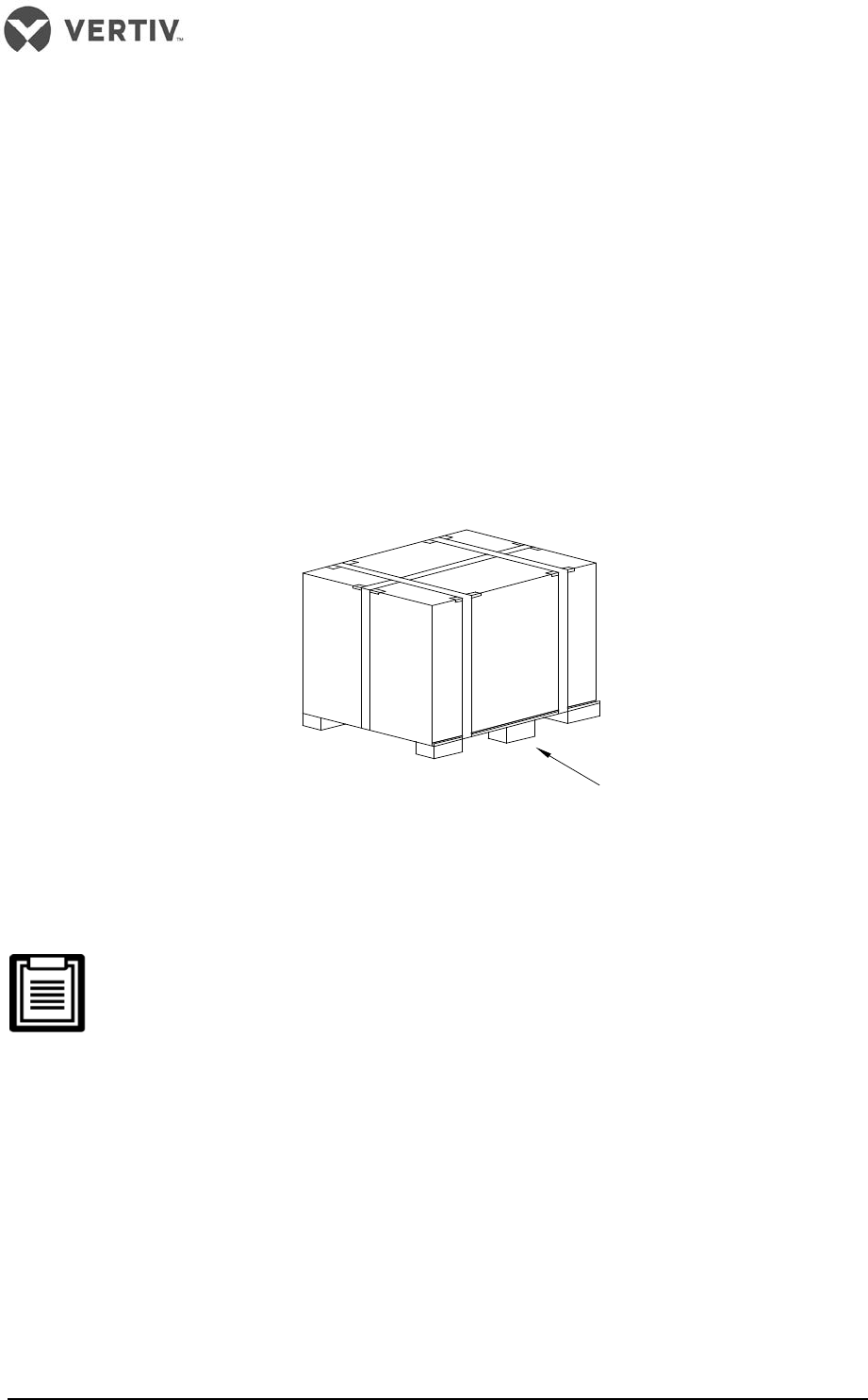

When a forklift is used, insert the tines of the forklift shown in Figure 2-1 (taking the single fan

condenser for example).

Forklift

direction

Figure 2-1 Forklift direction

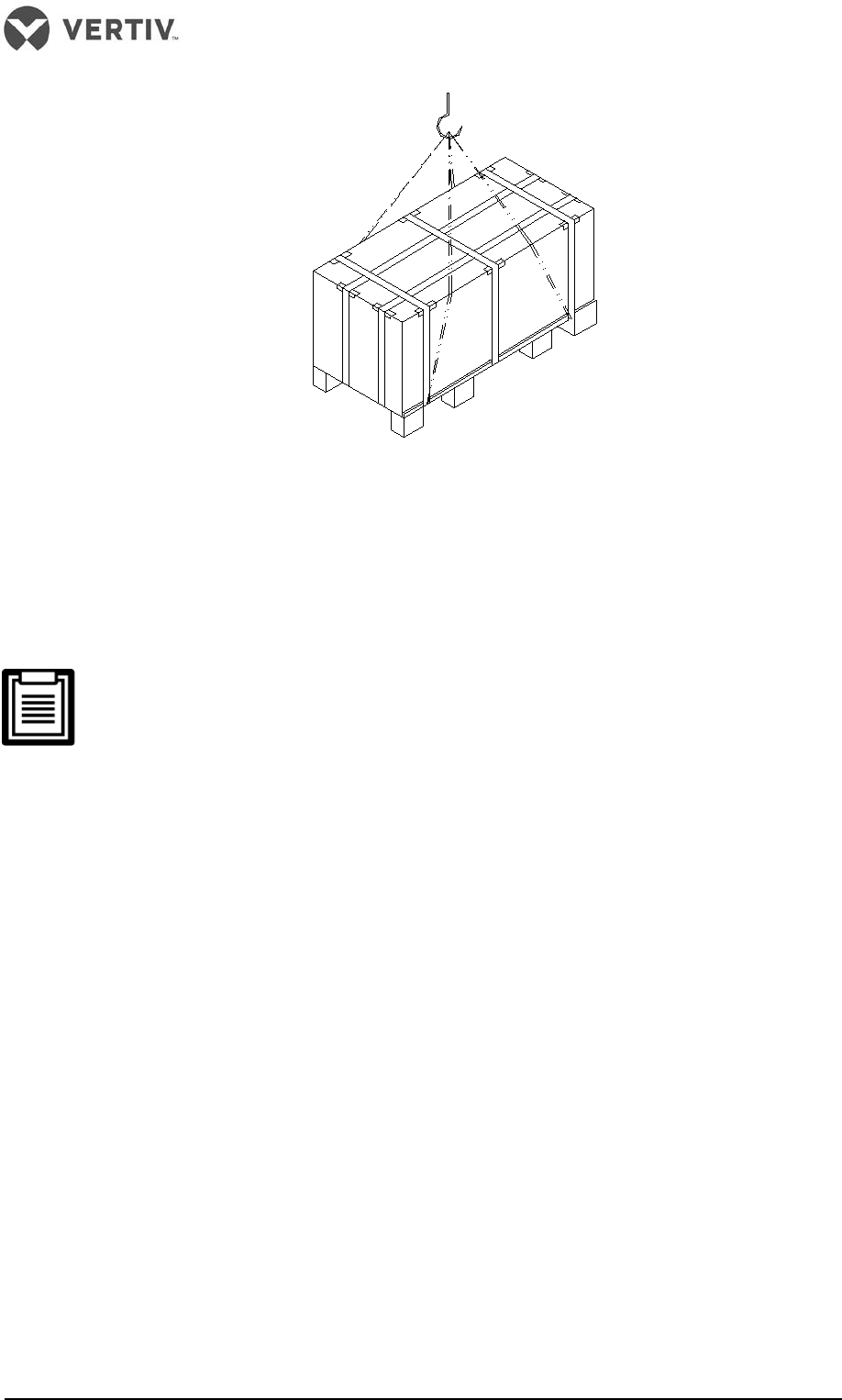

When a crane is used, refer to Figure 2-2 to lift the package (taking the double fans condenser

for example).

When lifting the package, fix the cable by leading it through the slots located at the

bottom of the pallet. Otherwise, the cable may slide during the lifting process, and

the package may fall to the ground, damaging the pipes inside and resulting in

system leakage.

Vertiv I Liebert Air Cooled Condenser I User Manual 8

Figure 2-2 Crane lifting

Unpacking

Remove the timber frame package and foam of the condenser but reserve the protection

cardboard of fins. The protection cardboard of fins and the cushion pad of U tube located at

the end of the condenser should be removed after the condenser is in its installation position.

1.

I

f the condenser is to be placed horizontally, you should complete the installation

of legs while the condenser is located vertically.

2.

Whe

n moving the condenser by hand, to avoid distortion and system leakage, do

not touch the copper pipes.

Inspection

After the product arrival, you should check the accessories against the packing list. If any parts

are found missing or damaged, please report to the carrier immediately. If any covert damage is

found, please report to the carrier and the distributor immediately.

2.2 Installation Notes

The installation notes of the condenser are as follows:

1.

T

o ensure the heat dissipation capacity, install the condenser in the place with smoo

th

airflow. Do not install it where the coil of the condenser may be obstructed by dust or snow.

Ensure that there is no steam or waste heat around.

2. If possible, the horizontal installation is recommended to reduce the noise.

3.

T

he condenser should be installed away from the residential areas (≥ 15m

).

Vertiv I Liebert Air Cooled Condenser I User Manual 9

4. Be careful not to damage the waterproof layer and observe the local regulations when the

condenser is installed on the roof of the building.

5. Position the condenser higher than the indoor unit to ensure normal oil return.

6. Follow the installation arrows on the condenser for correct installation direction.

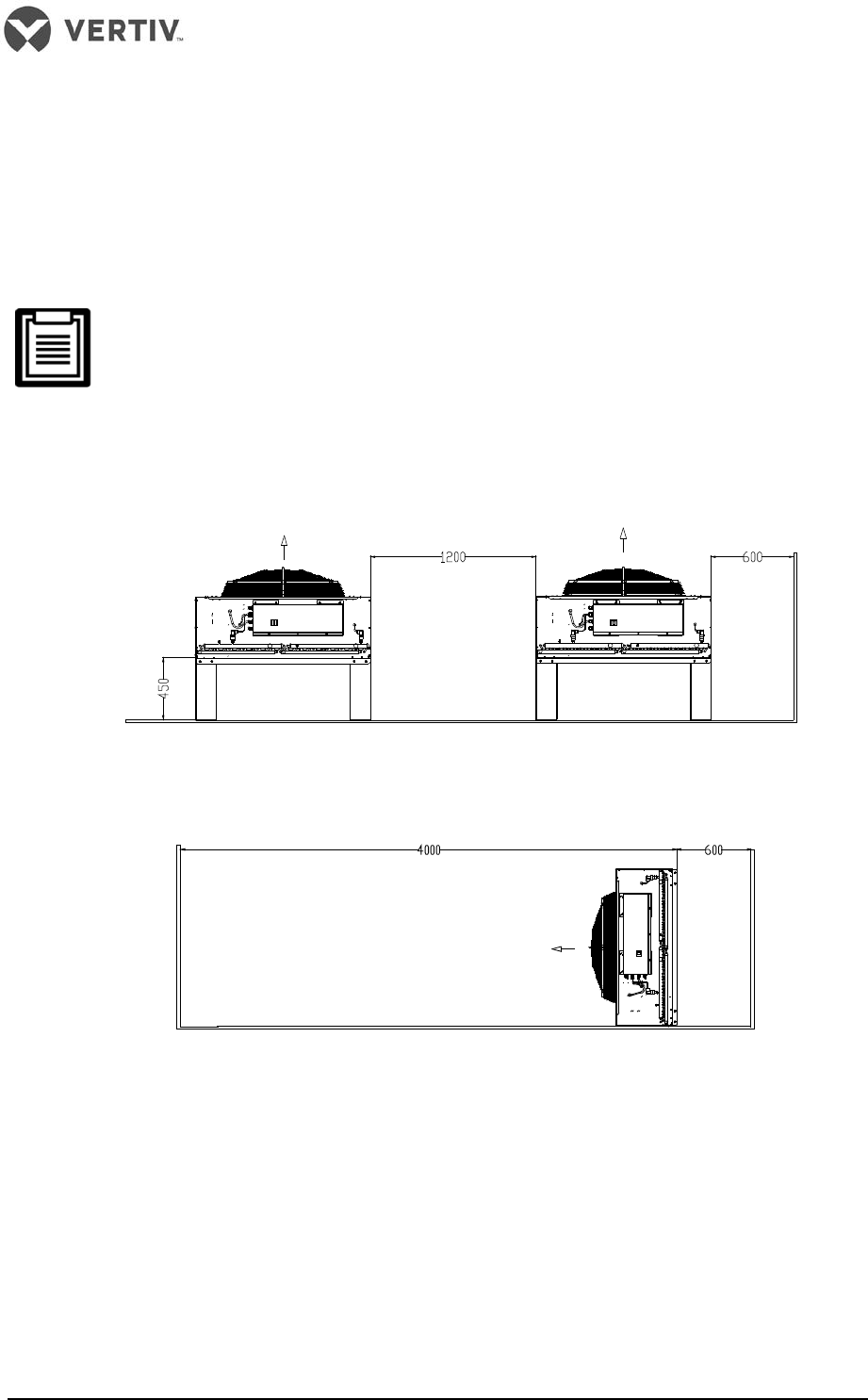

2.3 Space Requirements

1. A 4000mm clearance is required around the condenser air outlet.

2. 600mm service spaces are required on the four sides of the condenser.

The condenser needs sufficient installation and service space around the installation place.

The specific space requirements are shown in Figure 2-3 and Figure 2-4.

Figure 2-3 Horizontal installation space requirement (unit: mm)

Figure 2-4 Vertical installation space requirement (unit: mm)

Airflow

Airflow

Airflow

Vertiv I Liebert Air Cooled Condenser I User Manual 10

2.4 Installation Procedures

Before commencing installation hot works, release all nitrogen holding charges

from the indoor and outdoor units.

Installing pipelines

1. Protect copper pipes from heat sources. Isolate copper pipes from structures or

other obstacles using rigid supports. Avoid dust, water vapor and irrelevant objects

from entering copper pipes.

2

. U

se a good quality, silver-based solder for all brazed connections. Use

refrigeration grade copper pipes and fittings throughout the installation. Purge all

pipes with nitrogen during brazing to prevent oxidation.

1. Identify the pipe sizes

R

efer to Installing Unit Pipes in Liebert LSF Air Conditioner User Manual for pipe sizes.

2. Identify the condenser installation height

Refer to Installing Unit Pipes in Liebert LSF Air Conditioner User Manual for installation height.

3.

I

nstall the pipe

s

I

nstall the pipes according to local and national codes and standards.

Connecting external power (external power supply of the condenser)

1.

I

dentify the cable specifications

Select the power supply cables and start/stop signal cables of the condenser according to site

conditions, such as the distance between the indoor unit and the condenser.

Table 2-1 Operation current of fan under 400V voltage

Condenser Model FLA (A)

LSF24 1.65

LSF32 1.05

LSF38, LSF42, LSF52, LDF42, LDF52 2.4

LSF62, LSF70, LDF62, LDF70 3.3

LSF76, LSF85, LDF76, LDF85 4.8

Vertiv I Liebert Air Cooled Condenser I User Manual 11

1. It is recommended to use the 20AWG (0.52mm2) cable as the condenser

start/stop signal cable.

2. The (outdoor) air cooled condenser requires a three-phase, neutral and earth

power supply. The indoor unit is the recommended point of connection for this

electrical service and includes a three-pole circuit breaker rated at 16 amps.

3. The cables should not contact hot objects, such as the copper pipe and water

pipe without insulation, to avoid damaging the insulation layers.

4. The cables should be connected in accordance with the local regulations.

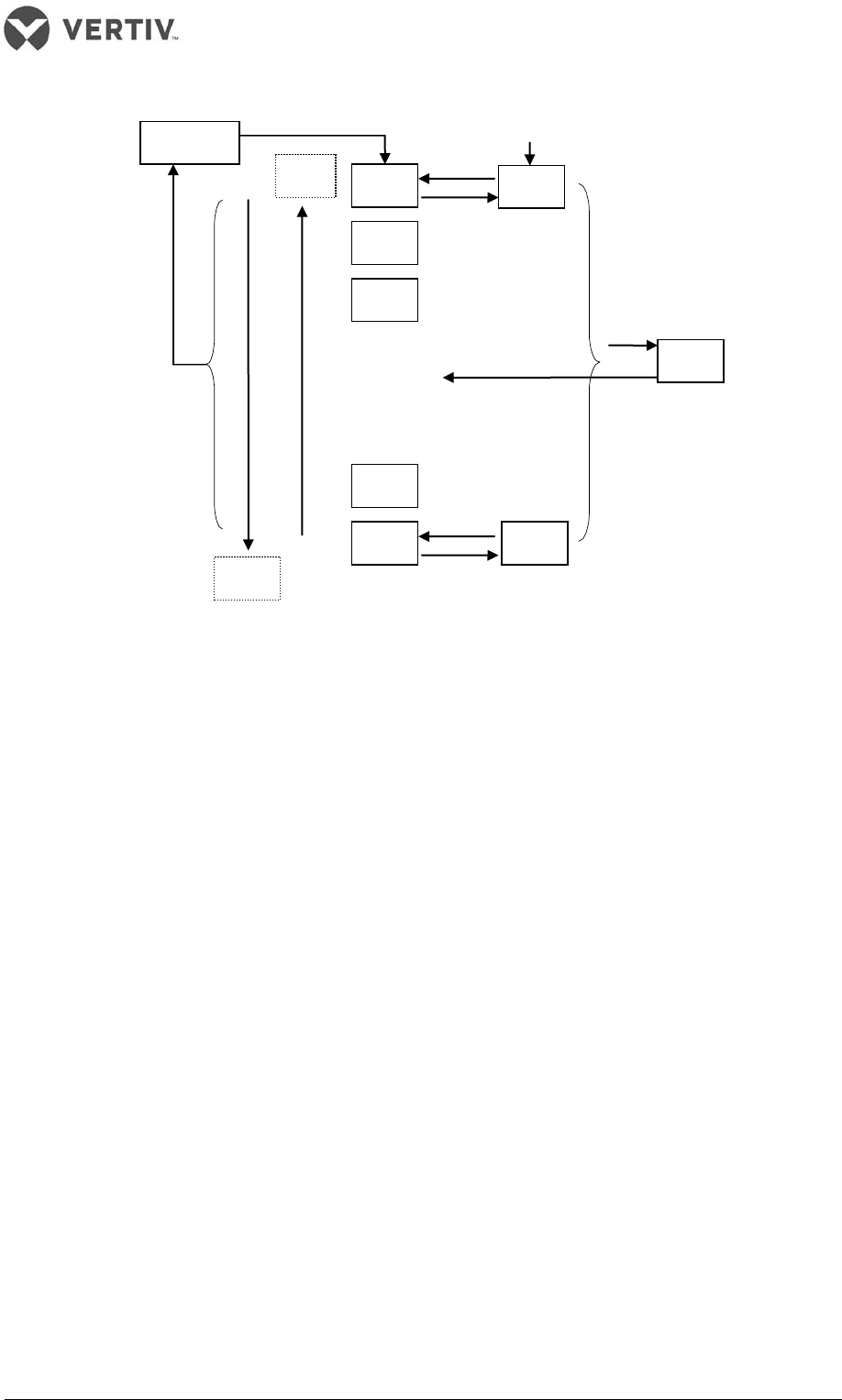

2. Connect the cables

Refer Figure 2-5, Figure 2-6 and C

ircuit Diagram for the connections of external power cables.

Figure 2-5 Connection figure of single fan external power cables (taking LDF42 for example)

Figure 2-6 Connection figure of double fans external power cables (taking LDF62 for example)

1. The external power cables enter the electrical control box through the

waterproof joint of external power cable whose inner diameter is Φ10mm.

2. The compressor signal cables enter the electrical control box through the

waterproof joint of external power cable whose inner diameter is Φ6mm.

3. After connecting the external power cables, apply waterproof sealant treatment

to ensure the good waterproof performance of electrical control box.

Waterproof joint of Compressor signal

Waterproof joint of external power

cables by others

Accessing terminal of

external power

supply (single fan)

Fan speed controller board

Fan speed controller board

Accessing terminal of

external power

supply (double fan)

Waterproof joint of

Compressor signal

Waterproof joint of

external power

cables by others

Vertiv I Liebert Air Cooled Condenser I User Manual 12

4. The phase sequence of three-phase AC input (L1, L2, L3) must be correct.

Otherwise, the fan speed controller will generate the phase loss alarm, and ther

e

will be no AC output.

5. For dual circuit condenser (such as LDF42, LDF52, LDF62, LDF70, LDF76 and

LDF85), the four condenser start/stop signal cables should be paralleled at the

terminal block of indoor unit before connection; for single circuit condenser, the

two condenser start/stop signal cables can be connected directly.

Charging refrigerant and adding cooling

oil

R

efer to Installing Unit Pipes in Liebert LSF Air Conditioner User Manual for charging

refrigerant and adding cooling oil.

Vertiv I Liebert Air Cooled Condenser I User Manual 13

Chapter 3 Application of Fan Speed Controller

This chapter introduces the use of the fan speed controller, which includes the definitions of

wiring terminals, introduction of human-machine interface (HMI) and operation of HMI. This

chapter is mainly provided for the factory maintenance personnel. It is recommended that

users should not operate the fan speed controller unless necessary.

The configured fan number must be the same as the number of the actual fans, or

else a false alarm will be generated. Refer to Configuration data main menu

interface in 3.3.2 Main Menu Interface for detailed settings.

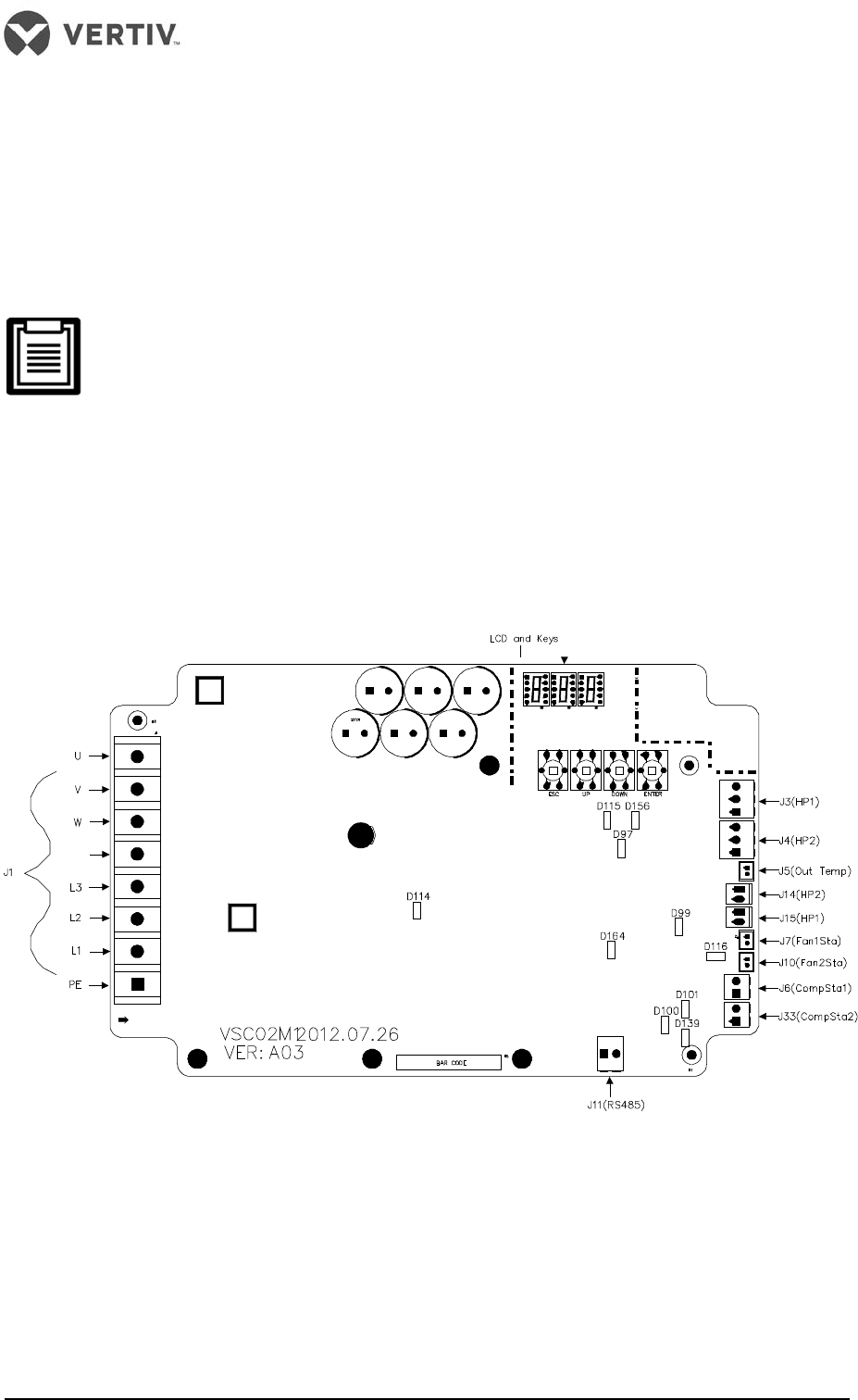

3.1 Wiring Terminals

The wiring terminals are located on the fan speed controller board (Refer Figure 2-5 and

Figure 2-6). Their distribution is shown in Figure 3-1 and the definitions are listed in Table 3-1.

Refer to Circuit Diagram for detailed connections.

Figure 3-1 Layout of wiring terminals

Vertiv I Liebert Air Cooled Condenser I User Manual 14

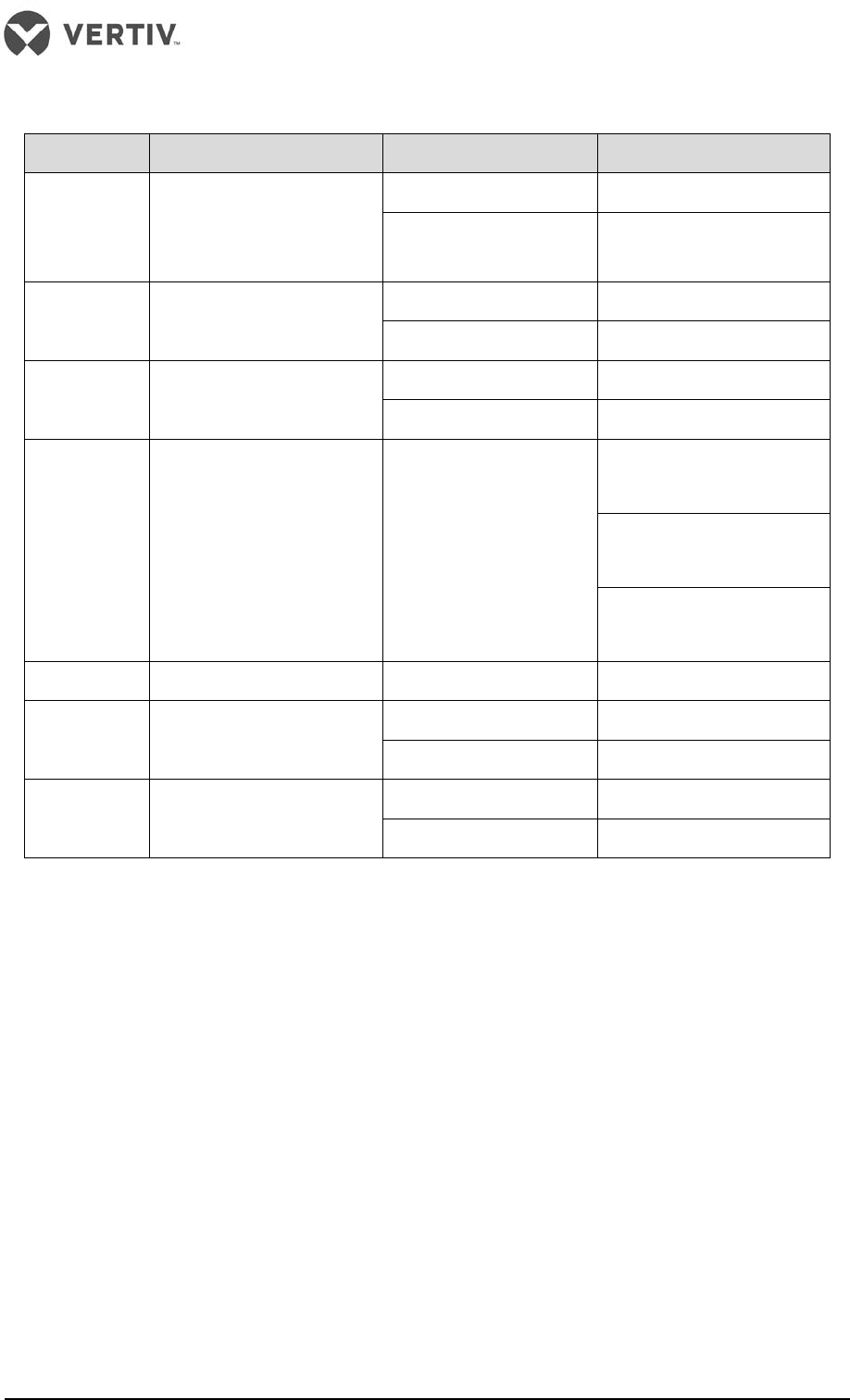

T

able 3-1 Definitions of wiring terminals

Silk print Definition Definition of pins

J1 AC I/O terminal

PE: protection earth

L1, L2, L3: three-phase AC input

U, V, W: three-phase AC output, which connects

with the power supply terminals

The middle terminal pin without logo is reserved

J3 (HP1)

Input terminal of voltage

pressure sensor 1 (spare)

Pin 1: positive terminal of 5V power

Pin 2: input terminal of 0.5V ~ 4.5V pressure

voltage signal

Pin 3: negative terminal of 5V power

J4 (HP2)

Input terminal of voltage

pressure sensor 2 (spare)

J15 (HP1)

Input terminal of current

pressure sensor 1

Pin 1: positive terminal of 12V power

Pin 2: input terminal of 4mA ~ 20mA pressure

current signal

J14 (HP2)

Input terminal of current

pressure sensor 2

J5 (Out Temp)

Input terminal of ambient

temperature sensor (spare)

Pin 1: input terminal of temperature signal

Pin 2: signal ground

J11 (RS485)

Serial communication interface

(used for maintenance)

Pin 1: RS485+

Pin 2: RS485-

J7 (Fan1Sta)

Detecting terminal of fan 1 over

temperaturestate

Pin 1: output terminal of 19Vac signal

Pin 2: return terminal of 19Vac signal

J10 (Fan2Sta)

Detecting terminal of fan 2 over

temperature state

J6 (CompSta1)

Detecting terminal of

compressor1 state

Pin 1: output terminal of 19Vac signal

Pin 2: return terminal of 19Vac signal

J33 (CompSta2)

Detecting terminal of

compressor2 state

3.2 HMI

The fan speed controller operation and setup is provided through indicators, RS485 serial

communication port, keys and LCD.

Vertiv I Liebert Air Cooled Condenser I User Manual 15

Indicators

There are ten indicators (Refer Figure 3-1) on the fan speed controller board. Refer Table 3-2

for the functions of indicators.

Table 3-2 Functions of indicators

Silk print Definition Color State Function

D97

+5V Power

indicator

Yellow

On

The CPU circuit of fan speed controller

board is supplied with 5V power

Off The fan speed controller board is faulty

D115

+12V Power

indicator

Yellow

On

The fan speed controller board is supplied

with +12V power

Off

The fan speed controller board is faulty

D116

+24V Power

indicator

Yellow

On

The fan speed controller board is supplied

with +24V power

Off

The fan speed controller board is faulty

D139

VCOM Power

indicator

Yellow

On

The fan speed controller board is supplied

with VCOM power

Off

The fan speed controller board is faulty

D156

-5V Power

indicator

Yellow

On

The fan speed controller board is supplied

with -5V power

Off The fan speed controller board is faulty

D114

VCC_BOT Power

indicator

Yellow

On

The fan speed controller board is supplied

with VCC_BOT power

Off

The fan speed controller board is faulty

D99 Run indicator Green

On or off

The fan speed controller board is faulty

Blinking at 2Hz

(slowly)

The fan is not running

Blinking at 5Hz

(quickly)

The fan is running

D164 Alarm indicator Red

On

Fan speed controller detects an

alarm(alarms)

Off

No alarm

D100

RS485 sending

indicator

Green

On RS485 is sending data

Off

No data sending

D101

RS485 receiving

indicator

Green

On

RS485 is receiving data

Off

No data receiving

Vertiv I Liebert Air Cooled Condenser I User Manual 16

RS485 serial communication port

The RS485 serial communication port is a port to connect the computer using factory-defined

protocol. It is used for factory commissioning and maintenance.

Keys and LCD

The keys and LCD, which can realize the functions in Table 3-3, provide the HMIs for

maintenance personnel. Refer to 3.3 Operation Description of HMI for operation of keys and

LCD HMI.

Table 3-3 Function descriptions of keys and LCD

NO. Function Description

1

Query the acquisition data in real

time

The acquisition data include condensing pressure, ambient

temperature, output percentage, the state of fan enable singal

and the state of alarm

2

Query the current alarm data in real

time

The current alarm data include phase loss alarm, PIM over

temperature, fan 1 over temperature, fan 2 over temperature,

fan 1 over temperature locked, fan 2 over temperature locked,

pressure sensor failure, EEPROM read fault alarm, hardware

over current and bus over voltage

3

Query the historical alarm data in

real time

The latest saved 100 historical alarms can be queried

4

Modify the configured parameters in

real time

The configured parameters include running pressure,

pressure controlling range, minimum output frequency,

maximum output frequency, fan number and pressure sensor

type, refrigerant type, jump frequency 1, jump frequency 1

range, jump frequency 2, jump frequency 2 range, jump

frequency 3, jump frequency 3 range, the curve of frequency

control, manual mode, manual mode output frequency; or

resume the default values

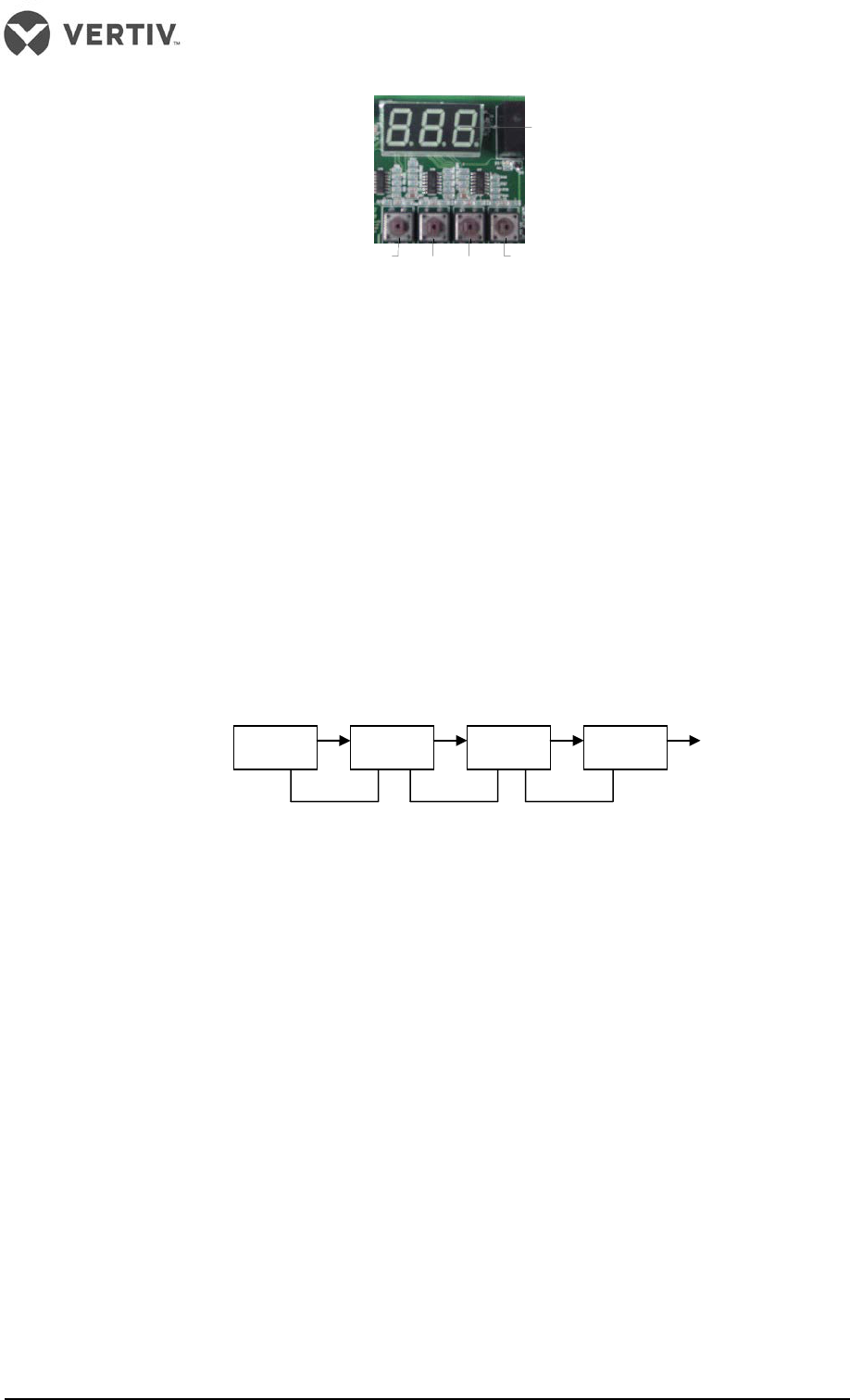

The keys and LCD are on the upper right corner of the fan speed controller board, as shown in

Figure 3-1. Their appearance is shown in Figure 3-2.

Vertiv I Liebert Air Cooled Condenser I User Manual 17

Figure 3-2 Keys and LCD

3.3 Operation Description Of HMI

3.3.1 Initial Interface

The LCD will alternately display ‘F00’ (the maximum pressure logo) and the larger of

condensing pressure 1 and condensing pressure 2 when the fan speed controller is powered

on initially.

The display order is shown in Figure 3-3 (the ‘16.1’ is only an example, and the actual value is

determined by the sampling result).

Figure 3-3 Display order of the initial interface

3.3.2 Main Menu Interface

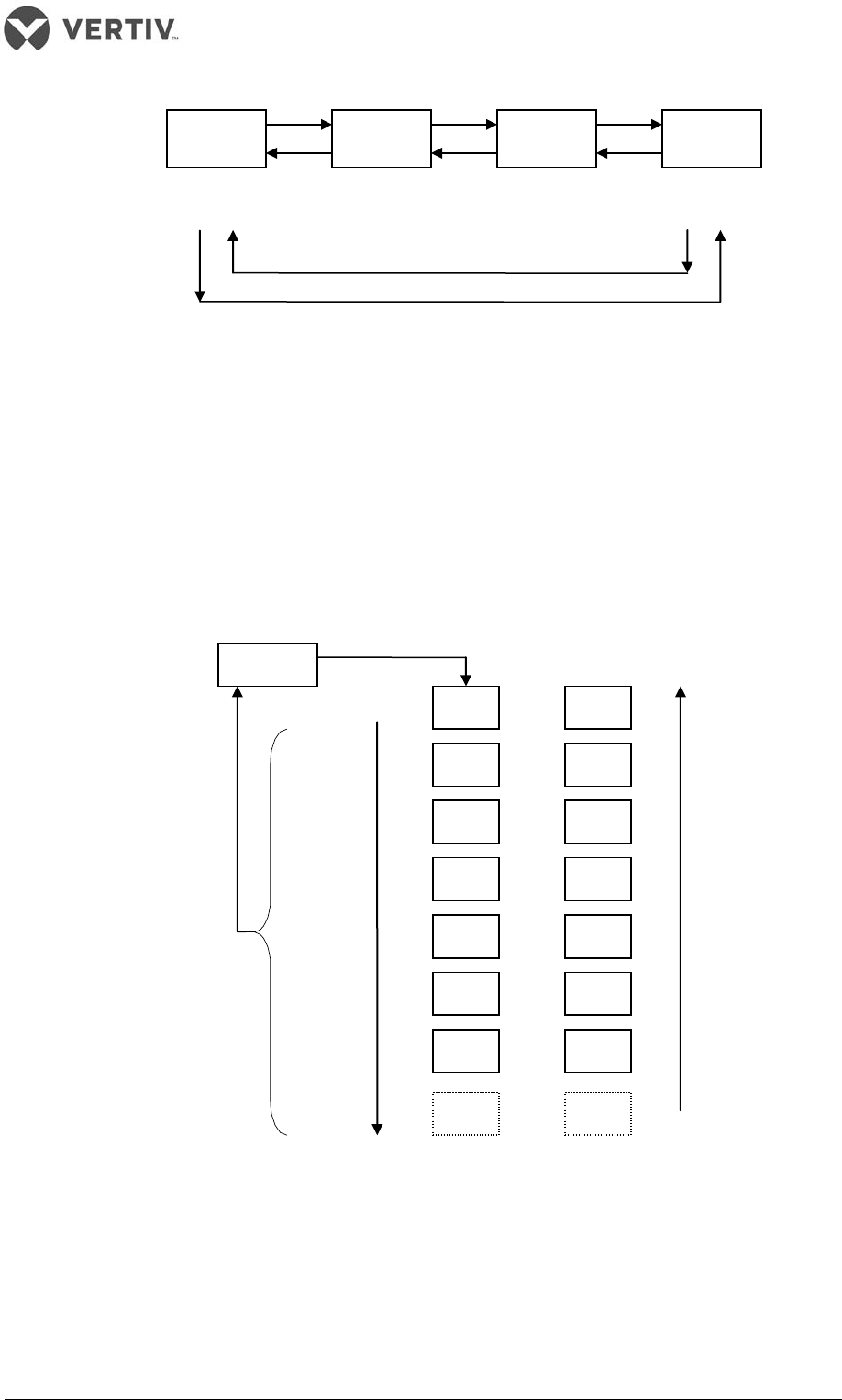

Press the ESC key on the initial interface, and the main menu interface will appear on

the LCD. The main menu interfaces include the analog main menu interface, current

alarm main menu interface, historical alarm main menu interface and configuration main

menu interface. Press the UP key and DOWN key to select a different main menu

interface, and press the ENT key to enter the submenu of the current main menu on the

main interface. The switching operation processes and orders of the main menus are

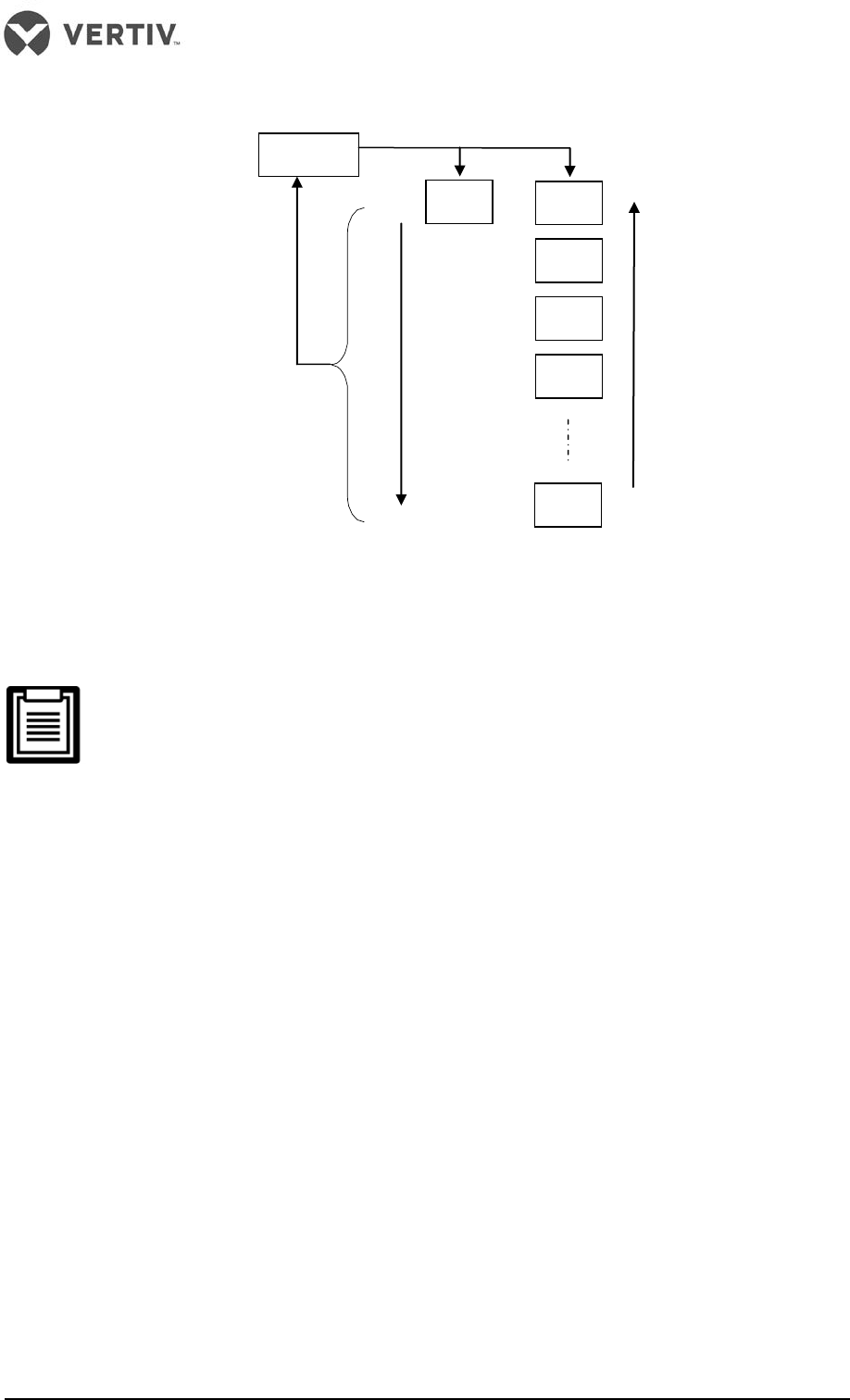

shown in Figure 3-4.

LCD

ESC key

DOWN key

ENT key

UP key

1s

1s

1s

F00 16.1 F00 16.1

Vertiv I Liebert Air Cooled Condenser I User Manual 18

Figure 3-4 Switching operation processes and orders of the main menus

Analog main menu interface

Press the ENT key to enter the analog submenu interface when the current main menu

interface shows ‘F--’ (the symbol of analog main menu). The switching operation processes

and orders of the analog submenu are shown in Figure 3-5, and the analog main menu ID

significances are shown in Table 3-4,

Figure 3-5 Switching operation processes and orders of the analog submenu

Analog main

menu interface

F――

A――

H――

C――

Current alarm main

menu interface

Historical alarm main

menu interface

Configure data

m

enu interface

DOWN key

DOWN key

DOWN key

UP key

UP key

UP key

DOWN key

UP key

F――

Analog main menu interface

F00

F01

F02

F03

F04

F05

F06

XX.X

XX.X

XX.X

*XX

_XX

On

OFF

DOWN

UP

ENT

F00

XX.X

ESC

Vertiv I Liebert Air Cooled Condenser I User Manual 19

Table 3-4 Analog main menu ID significances

Sub Menu ID Significance Display Remarks

F00

The maximum pressure

between the pressure 1 and

pressure 2

0~44.2Bar Condensing pressure

888 Sensor fault

F01 Pressure 1

0~44.2Bar Condensing pressure

888 Sensor fault

F02 Pressure 2

0~44.2Bar Condensing pressure

888 Sensor fault

F03 Ambient temperature -41℃~106℃

-41

℃

:The temperature

sensor is not connected

106

℃

:Temperature sensor

short

-40

℃

~105

℃

:Ambient

temperature

F04 Output percentage 0~100 Rated frequency 50/60Hz

F05 State of enable signal

0 ON

1 OFF

F06 State of alarm

0 ON

1 OFF

Current alarm main menu interface

Press the ENT key to enter the current alarm submenu interface when the current main menu

interface shows ‘A--’ (the symbol of current alarm main menu). The switching operation

processes and orders of the current alarm submenu are shown in Figure 3-6, and the Current

alarm main menu ID significances are shown in Table 3-5.

Vertiv I Liebert Air Cooled Condenser I User Manual 20

Figure 3-6 Switching operation processes and orders of the current alarm submenu

Table 3-5 Current alarm main menu ID significances

Alarm name Alarm number ID

phase loss alarm 00

PIM over temperature 01

fan 1 over temperature 02

fan 2 over temperature 03

fan 1 over temperature locked 04

fan 2 over temperature locked 05

pressure sensor failure 06

EEPROM read fault alarm 07

hardware over current 08

bus over voltage 09

Historical alarm main menu interface

Press the ENT key to enter the historical alarm submenu interface when the current main

menu interface shows ‘H--’ (the symbol of historical main menu). The switching operation

processes and orders of the historical main menu are shown in Figure 3-7.

A――

A00

A03

DOWN

UP

ENT

ESC

A09

A02

---

No Alarm

or

Current alarm main

menu interface

Vertiv I Liebert Air Cooled Condenser I User Manual 21

Figure 3-7 Switching operation processes and orders of the historical main menu

Configuration data main menu interface

The configuration data main menu interface is designed only for maintenance

personnel to set parameters, others are prohibited to operate it.

Press the ENT key to enter the configuration data submenu interface when the current main

menu interface sho

ws ‘C--’ (the symbol of configuration data main menu). The switching

operation processes and orders of the configuration data main menu are shown in Figure

3-8. and the configuration main menu interface ID significances are shown in Table 3-6.

H――

ENT

ESC

or

---

No Alarm

Historical alarm main menu interface

DOWN

UP

99.0

0.1

1.8

2.9

3.0

Vertiv I Liebert Air Cooled Condenser I User Manual 22

Figure 3-8 Switching operation processes and orders of the configuration data main menu

The configured parameters include running pressure, pressure controlling range, minimum

output frequency, maximum output frequency, fan number and pressure sensor type,

refrigerant type, jump frequency 1, jump frequency 1 range, jump frequency 2, jump frequency

2 range, jump frequency 2, jump frequency 2 range, the curve of frequency control, manual

mode, manual mode output frequency; or resume the default values.

C――

C00

C01

C02

C98

C99

13

0

DOWN

UP

ENT

…

…

ESC

ENT

ESC

888

ENT

Configuration value changed submenu

(using DOWN and UP keys)

C00

C99

ENT

ESC

…

ESC

Configuration main menu interface

Vertiv I Liebert Air Cooled Condenser I User Manual 23

T

able 3-6

Sub

menu ID

Significance Default

value

Range Remarks

C00 Running pressure Pset 13/13/21 11~15/11~15/19~23 Read and write

C01

Pressure controlling range

Pband

5/5/7 4~6/4~6/6~7 Read and write

C02

Minimum output frequency

fMin

10%fp 10%fp~50%fp Read and write

C03

Maximum

output frequency

fMax

fp 51%fp~100%fp Read and write

C04 Fan number 1 1~2 Read and write

C05

Pressure sensor type 2 or 1 1:voltage type;2:current

type;

Read and write

C06 Refrigerant type 1

1 : R22 ; 2 : R407C ; 3 :

R410A

Read and write

C07 Jump frequency 1(% fp) 0 0~100 Read and write

C08 Jump frequency 1 range 0.0 0.0Hz~0.5Hz Read and write

C09 Jump frequency 2(% fp) 0 0~100 Read and write

C10 Jump frequency 2 range 0.0 0.0Hz~0.5Hz Read and write

C11 Jump frequency 3(% fp) 0 0~100 Read and write

C12 Jump frequency 3 range 0.0 0.0Hz~0.5Hz Read and write

C13 Curve of frequency control, 0 0:V/F;1:V/F2 Read and write

C14 Manual mode 0 0:OFF;1:ON Read and write

C15

M

anual mode output

frequency

0 0%fp~100%fp

Read and write

C16 Software version 100 100~999 Read only

C17 Year of manufacture 11 0~99 Read only

C18 Month of manufacture 02 1~12 Read only

C19 Day of manufacture 28 1~31 Read only

C98 Clear alarm history 0 0~1(Clear alarm history) Read and write

C99 Resume the default values 0

0 ~ 1 (

Resume the default

values)

Read and write

Vertiv I Liebert Air Cooled Condenser I User Manual 24

Chapter 4 Maintenance and Troubleshooting

This chapter introduces the maintenance and troubleshooting of the condenser. Users should

check the condenser regularly and solve the problems in time.

1.

T

he maintenance of the condenser must be done by technicians.

2. Except for the commissioning items that must be carried out with power-on,

during maintenance, the power of the indoor unit and the air switch of the

condenser must be cut off.

4.1 Maintenance

Refrigeration system

1. Check that the refrigeration pipes are firmly fixed. The refrigeration pipes shall not shake

with the vibration of wall, earth or equipment frame. Otherwise, reinforce the refrigeration pipes

with fastening objects.

2.

C

heck that there is no oil on the accessories of all refrigeration pipes, and make sure that th

e

p

ipes do not leak.

Heat exchange

r

1

.

C

lean the fin of the heat exchanger regularly.

2.

C

lean the fin of the heat exchanger with compressed air or fin detergent (weakly alkaline) if

the condenser airflow is blocked. Inverse airflow is good when the compressed air is used.

3.

C

heck for damaged fins and maintain them in time.

4.

A

void snow accumulation around the condenser in winter.

Fan

Check that the fan runs normally. Check it for problems such as abnormal noise, vibration and

bearing failure.

Fan speed controller

Check that the fan speed controller board operates normally. If not, replace it as illustrated in

the following paragraph.

Note that the positions of the bolt installation holes on the fan speed controller

could be different on the actual product.

Vertiv I Liebert Air Cooled Condenser I User Manual 25

The fan speed controller is inside the electrical control box (Refer Figure 1-2 and Figure 1-3).

Rotate the isolation switch to ‘OFF’, and then remove the cover plate of the electrical control

box, as shown in Figure 4-1. Remove the cover plate of the electrical control box before

removing the fan speed controller board. Except for the seven bolts in Figure 4-2, other bolts

are prohibited to remove. The bolt 1 and bolt 2, which are used to fix the heat sink on the fan

speed controller board, must be fastened firstly. The heat sink must cling to the floor of the

electrical control box. After installing the heat sink, use other five bolts to fix the fan speed

controller board.

ON

OFF

F

igure 4-1 Fan speed controller board

Fan speed controller board

Bolt 2

Bolt 1

散热片

Heat sink

Figure 4-2 Removing the fan speed controller board

Vertiv I Liebert Air Cooled Condenser I User Manual 26

4.2 Troubleshooting

Refer Table 4-1 for alarm troubleshooting.

Table 4-1 Table of alarm troubleshooting

Alarm number

ID

Alarm name Cause Troubleshooting

A00

Phase loss

alarm

One phase or two phases of

three-phase voltage are lost

Check that the three-phase voltage

is correct

The fan speed controller board has a

hardware fault

Replace the fan speed controller

board and compare the result of two

boards

A01

PIM over

temperature

The fan cannot run normally Check that the fan runs normally

The fan speed controller board has a

hardware fault

Replace the fan speed controller

board and compare the result of two

boards

A02

A03

Fan 1 over

temperature,

Fan 2 over

temperature

The fan cannot run normally Check that the fan runs normally

The AC contactor supplying power

for fan has fault or its wire cuts off

Check the wiring of AC contactor;

detect the auxiliary contact state of

AC contactor

The fan speed controller board has a

hardware fault

Replace the fan speed controller

board and compare the result of two

boards

A04

A05

Fan 1 over

Temperature

locked, Fan 2

over

Temperature

locked

The fan cannot run normally Check that the fan runs normally

The AC contactor supplying power

for fan has fault or its wire cuts off

Check the wiring of AC contactor;

detect the auxiliary contact state of

AC contactor

The fan speed controller board has a

hardware fault

Replace the fan speed controller

board and compare the result of two

boards

A06

Pressure

sensor

The pressure sensor is not installed

or its terminal connection is poor

Check the wiring of pressure sensor

Vertiv I Liebert Air Cooled Condenser I User Manual 27

Alarm number

ID

Alarm name Cause Troubleshooting

failure

Jumper caps are not used to short

terminals J17 and J18 of current

pressure sensor

Install the jumper cap when the

current pressure sensor is

configured

Pressure sensor failed

Replace the pressure sensor and

compare the result of two boards

The fan speed controller board has a

hardware fault

Replace the fan speed controller

board and compare the result of two

boards

A07

EEPROM

read fault

The fan speed controller board has a

hardware fault

Replace the fan speed controller

board and compare the result of two

boards

A08

Hardware

over current

The fan cannot run normally Check that the fan runs normally

The fan speed controller board has a

hardware fault

Replace the fan speed controller

board and compare the result of two

boards

A09

Bus over

voltage

The power supply voltage is

abnormal

Check the power supply

The fan speed controller board has a

hardware fault

Replace the fan speed controller

board and compare the result of two

boards

Vertiv I Liebert Air Cooled Condenser I User Manual 28

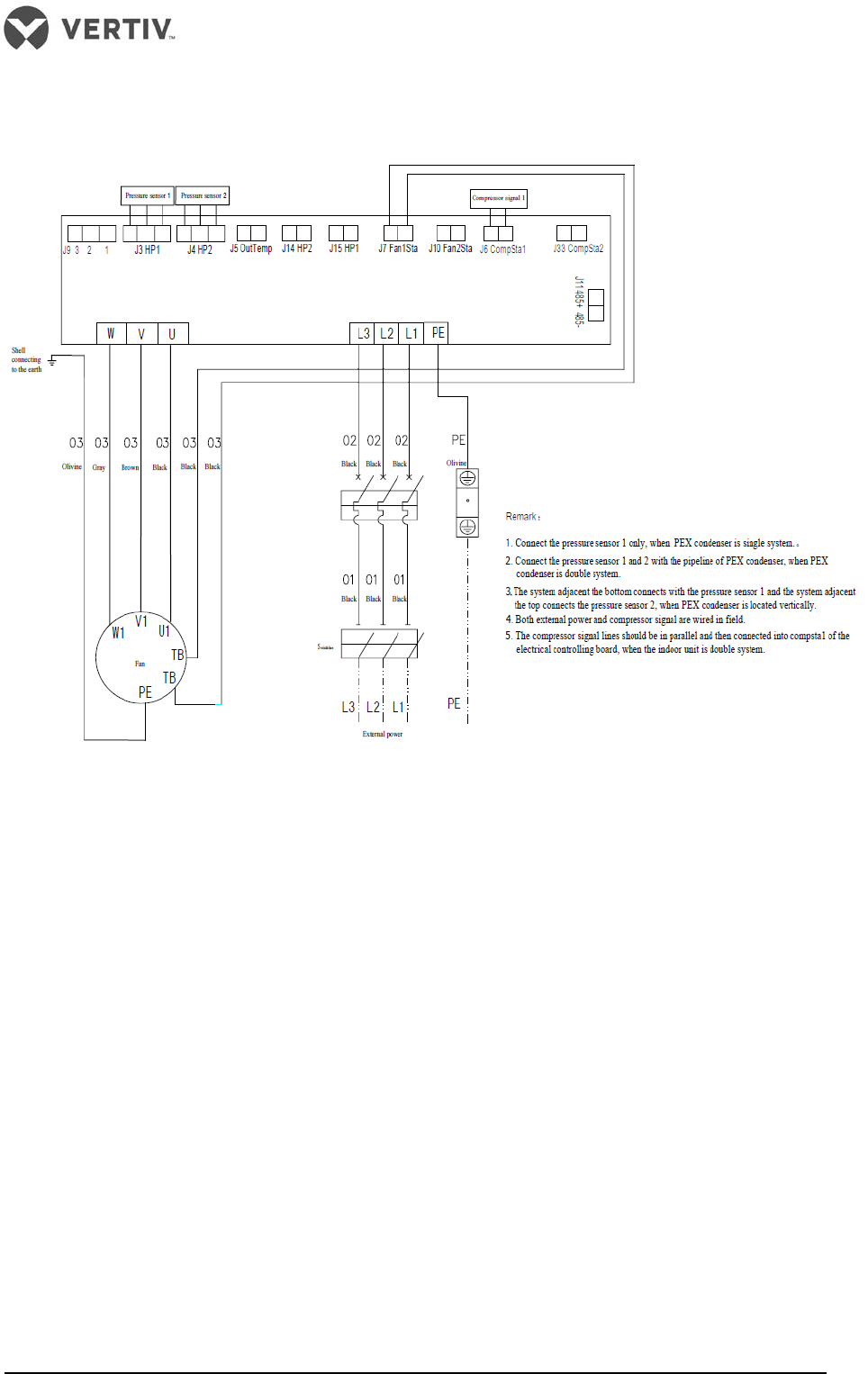

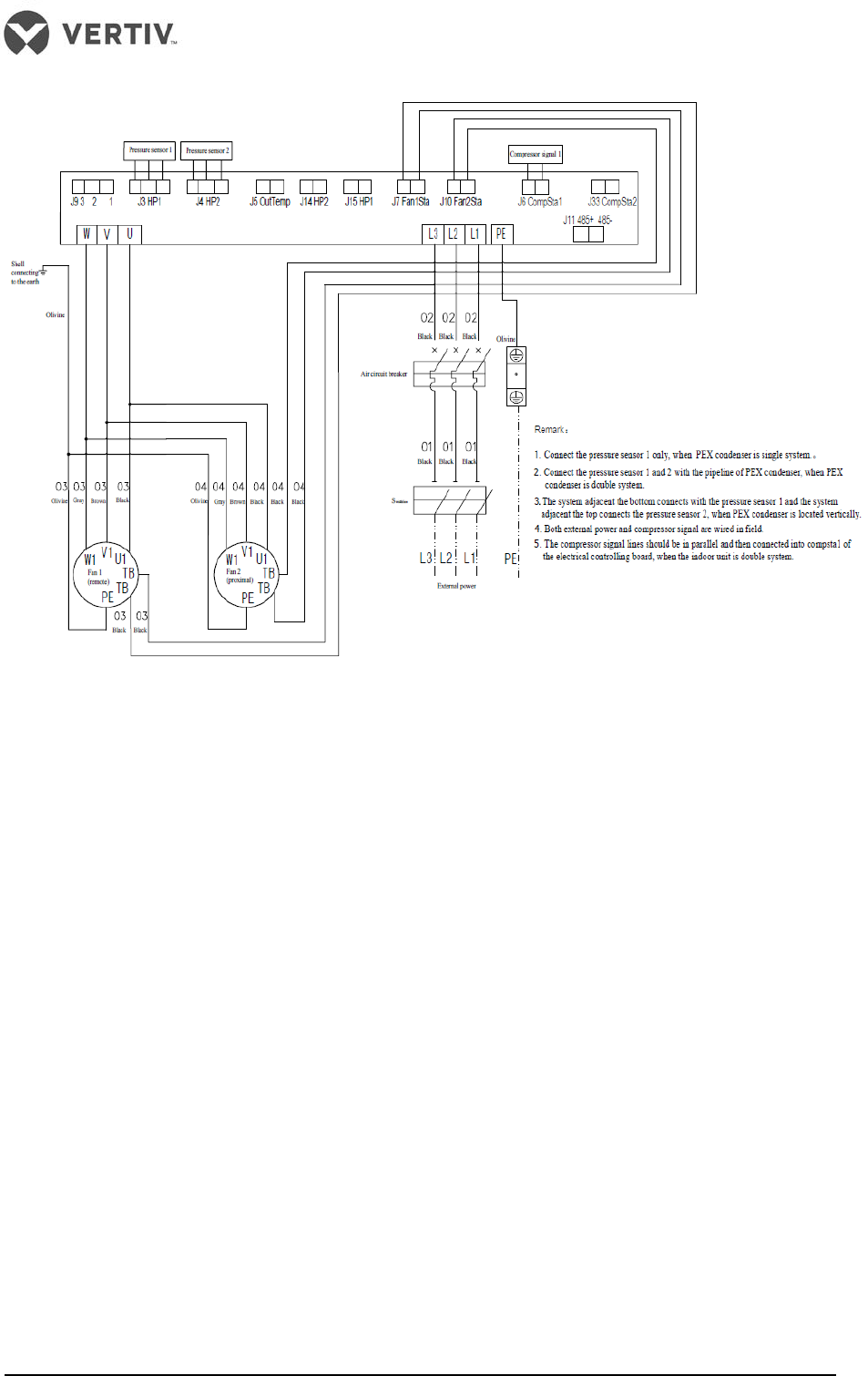

Appendix Circuit Diagram

Figure 1 Circuit diagram of the condenser with single fan

Vertiv I Liebert Air Cooled Condenser I User Manual 29

Figure 2 Circuit diagram of the condenser with double fans